June 19, 2019 feature

Graphene-based ink may lead to printable energy storage devices

Researchers have created an ink made of graphene nanosheets, and demonstrated that the ink can be used to print 3-D structures. As the graphene-based ink can be mass-produced in an inexpensive and environmentally friendly manner, the new methods pave the way toward developing a wide variety of printable energy storage devices.

The researchers, led by Jingyu Sun and Zhongfan Liu at Soochow University and the Beijing Graphene Institute, and Ya-yun Li at Shenzhen University, have published a paper on their work in a recent issue of ACS Nano.

"Our work realizes the scalable and green synthesis of nitrogen-doped graphene nanosheets on a salt template by direct chemical vapor deposition," Sun told Phys.org. "This allows us to further explore thus-derived inks in the field of printable energy storage."

As the scientists explain, a key goal in graphene research is the mass production of graphene with high quality and at low cost. Energy-storage applications typically require graphene in powder form, but so far production methods have resulted in powders with a large number of structural defects and chemical impurities, as well as nonuniform layer thickness. This has made it difficult to prepare high-quality graphene inks.

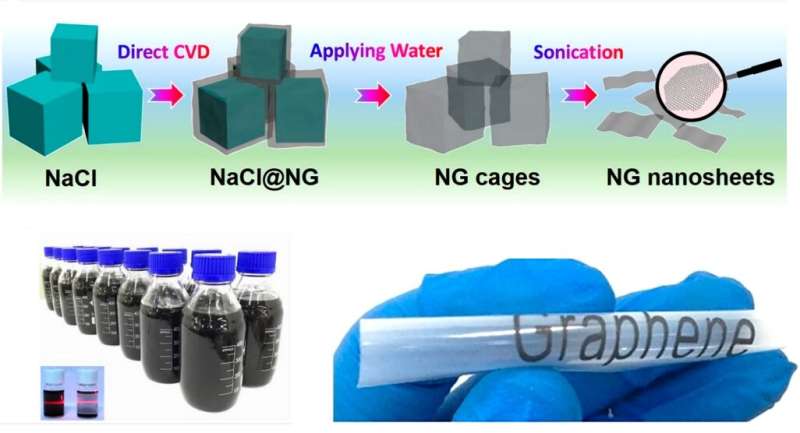

In the new paper, the researchers have demonstrated a new method for preparing graphene inks that overcomes these challenges. The method involves growing nitrogen-doped graphene nanosheets over NaCl crystals using direct chemical vapor deposition, which causes molecular fragments of nitrogen and carbon to diffuse on the surface of the NaCl crystals. The researchers chose NaCl due to its natural abundance and low cost, as well as its water solubility. To remove the NaCl, the coated crystals are submerged in water, which causes the NaCl to dissolve and leave behind pure nitrogen-doped graphene cages. In the final step, treating the cages with ultrasound transforms the cages into 2-D nanosheets, each about 5-7 graphite layers thick.

The resulting nitrogen-doped graphene nanosheets have relatively few defects and an ideal size (about 5 micrometers in side length) for printing, as larger flakes can block the nozzle. To demonstrate the nanosheets' effectiveness, the researchers printed a wide variety of 3-D structures using inks based on the graphene sheets. Among their demonstrations, the researchers used the ink as a conductive additive for an electrode material (vanadium nitride) and used the composite ink to print flexible electrodes for supercapacitors with high power density and good cyclic stability.

In a second demonstration, the researchers created a composite ink made of the graphene sheets along with binder material (polypropylene) for printing interlayers for Li−S batteries. Compared to batteries with separators made only of the conventional material, those made with the composite material exhibited enhanced conductivity, leading to an overall improvement in battery performance.

"In the future, we plan to exploit the direct chemical vapor deposition technique for the mass production of high-quality graphene powders toward emerging printable energy storage applications," Sun said.

More information: Nan Wei et al. "Scalable Salt-Templated Synthesis of Nitrogen-Doped Graphene Nanosheets toward Printable Energy Storage." ACS Nano. DOI: 10.1021/acsnano.9b03157

Journal information: ACS Nano

© 2019 Science X Network