Credit: SINE2020

Marialucia Longo and Tobias Schrader at the Jülich Centre for Neutron Science (JCNS) based at FRM II in Garching, Germany have been designing and testing a crystallization chamber to grow large protein crystals.

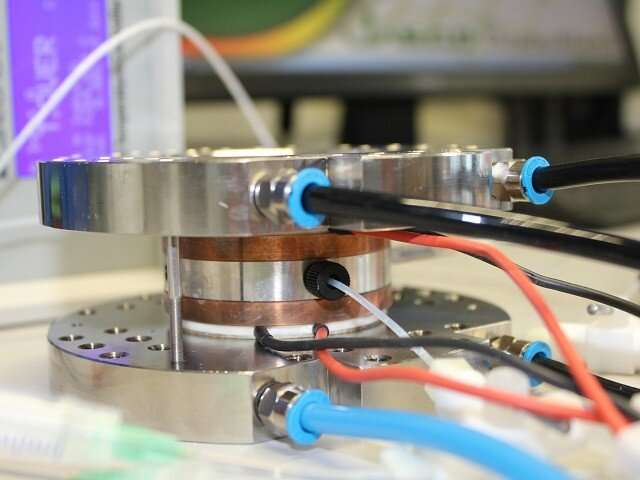

The chamber consists of two round stainless steel holders that incorporate Peltier heating elements, to control the temperature conditions, and a glass window to allow crystal growth to be monitored. The circular design facilitates an even temperature distribution to hopefully provide uniform temperature control in all directions.

Between the holders, a Teflon "spacer" is placed that forms the crystallization chamber itself, where all the action takes place. The spacer module is interchangeable to allow different configurations and provide a choice of crystallization methods (currently, vapour diffusion and batch crystallization spacers are available). As well as having a compartment for the crystal to grow in, these spacers also have pipe inlets and outlets for transporting protein solutions in and out. The spacers were designed and 3-D printed with the help of engineers at the Forschungszentrum Jülich in western Germany.

Post-doctoral researcher Marialucia Longo worked on the design and production of the apparatus for over a year, with expert help from Neils Lumma at Jülich. It is now in the testing phase. Longo started with hen egg white lysoyzme, as it is a well-known protein and forms big crystals quickly and easily. Other potential candidates are thermolysin and streptavidin, as so far, large crystals of these have been elusive. Streptavidin would be a particularly interesting molecule to study with neutrons, as not a lot is known about the hydrogen bonds to the biotin ligand within the structure. Making a crystal big enough to study with neutron techniques could shed light on this.

However, Longo confronts many obstacles and still has plenty of problems to solve. Not least because, with a background in DNA and inelastic scattering, she has first had to learn about proteins and elastic scattering.

Then there have been issues in the apparatus itself:, including unwanted bubbles in the chamber, inadequate performance of the sealing and unreliable temperature control. Particularly frustrating are the user-unfriendly heating elements. Tweaking the temperature using knobs and waiting two minutes for the temperature controller to resume normal operation has proved time-consuming and difficult. It is anticipated that a computer link to the temperature controller may enable the temperature to be stepped down gradually, e.g. by one degree a day. This requires development, but could aid the quest for growing bigger crystals.

Ultimately, the team's ambition is to use this apparatus to produce crystals for use on the instrument BIODIFF, a sophisticated instrument that ideally requires a crystal volume of at least 0.1 mm3. BIODIFF is a monochromatic single crystal diffractometer—a joint project of the FRM II (TUM) and JCNS (Forschungszentrum Jülich) run by Tobias Schrader and Andreas Ostermann, who has also been a big help on this project.

So far, the biggest crystals they have grown are 0.2 mm3 using the model protein lysozyme. As SINE2020 reaches its end, this project will continue with extra funding provided by Forschungszentrum Jülich.

Provided by CORDIS