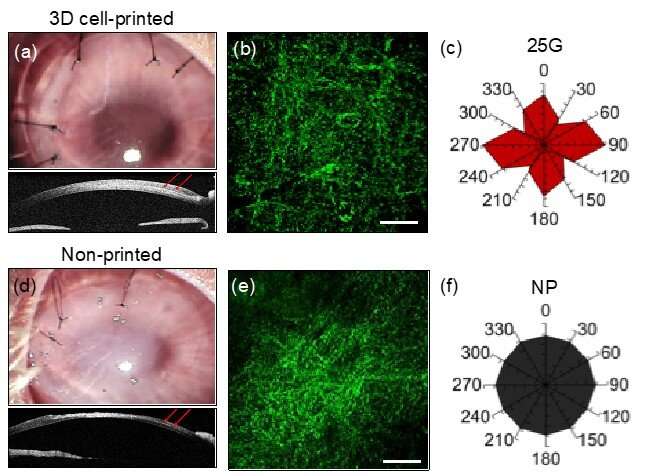

In vivo (a-c) and in vitro (d-f) evaluation results of 3D cell-printed and non-printed corneal implants. Optical images from slit lamp examination, 2D cross-sectional OCT images (a, d), and SHG images of non-specific collagen (b, e) with Distribution analysis of collagen fibrillar orientation (c, f). In 3D cell-printed group, higher transparency was exhibited compared to non-printed group and corneal stromal pattern by shear-induced collagen alignment was reconstructed similar to that in human cornea. Credit: POSTECH

When a person has a severely damaged cornea, a corneal transplant is required. However, there are 2,000 patients waiting for the cornea donation in the country as of 2018, and they wait for six or more years on average for the donation. For this reason, many scientists are attempting to develop an artificial cornea. The existing artificial cornea uses recombinant collagen or is made of chemical substances such as synthetic polymer. Therefore, it does not incorporate well with the eye, nor is it transparent after the cornea implant.

Professor Dong-Woo Cho of Mechanical Engineering, Professor Jinah Jang of Creative IT Convergence Engineering, and Ms. Hyeonji Kim at POSTECH, collaborating with Professor Hong Kyun Kim of Ophthalmology at Kyungpook National University School of Medicine, 3-D printed an artificial cornea using a bio-ink made of decellularized corneal stroma and stem cells. Because this cornea is made of corneal tissue-derived bio-ink, it is biocompatible, and 3-D cell printing technology recapitulates the corneal microenvironment, so its transparency is similar to the human cornea. This research is recently published on Biofabrication.

The cornea is a thin outermost layer that covers the pupil and it protects the eye from the external environment. It is the first layer that admits light and therefore it needs to be transparent, move as the pupil moves, and have flexibility. However, it has been limited to develop an artificial cornea using synthetic biocompatible materials because of different cornea-related properties. In addition, although many researchers have tried to repeat the corneal microenvironment to be transparent, the materials used in existing studies have limited microstructures to penetrate the light.

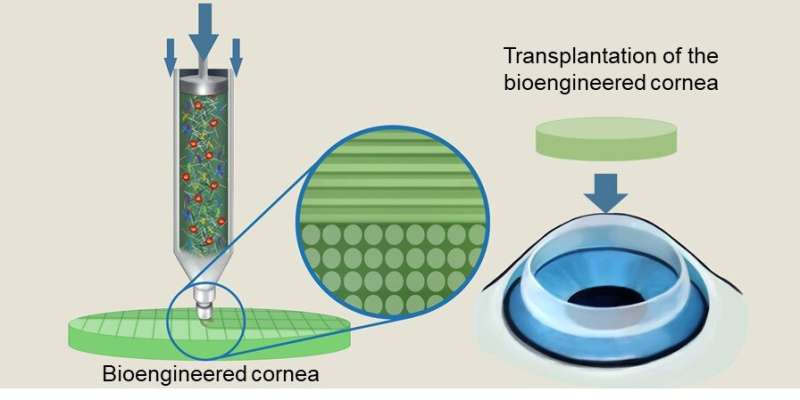

Schematic illustration of the alignment of collagen fibers within the nozzle during bioink extrusion. Credit: POSTECH

The human cornea is organized in a lattice pattern of collagen fibrils. The lattice pattern in the cornea is directly associated with the transparency of cornea, and many researches have tried to replicate the human cornea. However, there was a limitation in applying to corneal transplantation due to the use of cytotoxic substances in the body, their insufficient corneal features including low transparency, and so on. To solve this problem, the research team used shear stress generated in the 3-D printing to manufacture the corneal lattice pattern and demonstrated that the cornea by using a corneal stroma-derived decellularized extracellular matrix bio-ink was biocompatible.

In the 3-D printing process, when ink in the printer comes out through a nozzle and passes through the nozzle, frictional force which then produces shear stress occurs. The research team successfully produced transparent artificial cornea with the lattice pattern of human cornea by regulating the shear stress to control the pattern of collagen fibrils.

The research team also observed that the collagen fibrils remodeled along with the printing path create a lattice pattern similar to the structure of native human cornea after 4 weeks in vivo.

Professor Jinah Jang said, "The suggested strategy can achieve the criteria for both transparency and safety of engineered cornea stroma. We believe it will give hope to many patients suffered from cornea related diseases."

More information: Hyeonji Kim et al, Shear-induced alignment of collagen fibrils using 3D cell printing for corneal stroma tissue engineering, Biofabrication (2019). DOI: 10.1088/1758-5090/ab1a8b

Journal information: Biofabrication

Provided by Pohang University of Science & Technology (POSTECH)