Djalal Mirzayev. Credit: SUSU

Researchers from South Ural State University are working on producing an innovative, super-light, and super-strong kind of steel called bainite. This new material has potential applications in the aviation industry, mechanical engineering and the defence industry.

The developments have been published in Physics of Metals and Metallography. The authors of the article are Doctor of Sciences (Physics and Mathematics), Professor Djalal Mirzayev and Associate Professor of the Department of Optoinformatics of the SUSU Institute of Natural Sciences and Mathematics Ivan Buldashev.

Highly Strong and Malleable Steel

Steel is an alloy of iron and carbon, but depending on the temperature the iron is heated to, it is possible to obtain different steel structures. This is because within the interval of zero to 911 degrees Celsius, the properties of iron change completely. At a temperature lower than 911 degrees Celsius, austenite enters a more malleable and soft phase called ferrite, which is formed with slow cooling. In manufacturing, ferrite is used for machining. However, with shock cooling, austenite forms a superhard phase called martensite.

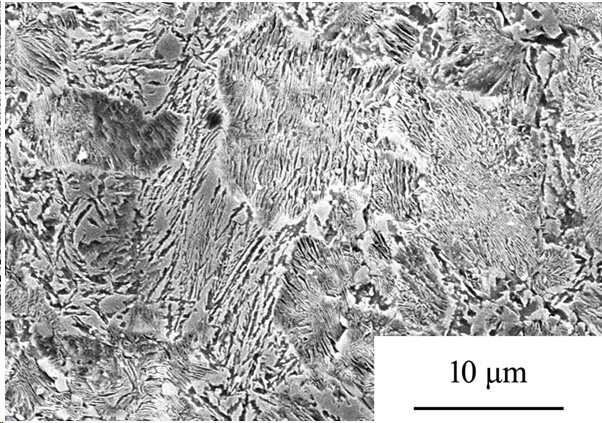

Structure of the bainite phase Fe-Si-Mn-Cr-V of still under a scanning electron microscope Credit: SUSU

"Martensite is a solid phase of steel, since during quick cooling, carbon is unable to separate fully as carbide and gets 'stuck' in the structure. In addition, during this kind of cooling, many microscopic defects appear – dislocations, which are not dangerous, but weaken the steel. Martensite is simultaneously a hard and brittle structure. Our goal is to create steel that maintains the high hardness of martensite and sufficient malleability, and is therefore stronger," says Djalal Mirzayev.

New steel for the oil industry

The basis of the current research is bainite, which is similar to martensite. It is produced by adding such elements as nickel, chrome, manganese and silicon. Maintaining the highest level of strength, bainite has a higher malleability than martensite. However, the malleability of bainite is not ultimate. The researchers from SUSU are working on obtaining carbide-free bainite, which will make it possible to increase its impact resistance, since carbide particles are stress concentrators that stimulate fracture. One more important aspect is cutting the time of production required for this kind of steel.

It is important to note that this new steel will become 15 to 30 percent stronger. It could find application in the defence industry and the oil industry. Pipes made from carbide-free bainite will not only have high impact resistance, they will also have durable strength in arctic climates. In the future, the scientists will work on searching for the optimal composition of new steel, the properties of which will depend on the industry the material will be intended for.

More information: I. L. Yakovleva et al. Structural Aspect of Isothermal Bainitic Transformation in High-Carbon Manganese–Silicon Steel, Physics of Metals and Metallography (2018). DOI: 10.1134/S0031918X18100149

Provided by South Ural State University