3-D experiments shed new light on shape memory alloys

Shape memory alloys are well known for their remarkable properties—superelasticity, shape memory and actuation allow them to be crumpled up and then spring back to a "remembered" original shape.

But the advanced material remains drastically underutilized in commercial applications, uses that could include morphing the shape of airplane structures to make flight more efficient or deploying communication dishes and solar arrays in space.

Researchers from Colorado School of Mines are working to better understand how their complex internal microstructures change during shape memory behaviors and the results of their first-of-their-kind experiments were recently published by three major materials science and mechanics journals, Acta Crystallographica, Journal of the Mechanics and Physics of Solids and Scripta Materialia.

"Discovered over 70 years ago, the promise of shape memory alloys (SMAs) has led to over 10,000 patents in the U.S. and 20,000 worldwide. However, that promise has not been matched by its technological impact—only a limited number of these 20,000 SMA patents have been realized as commercially viable products," said Ashley Bucsek Ph.D. '18, lead author of the three papers and now a President's Postdoctoral Fellow at the University of Minnesota. "The story is similar for many other advanced materials, taking decades to move from development to implementation. One reason for this gap between development and implementation is that researchers are literally just scratching the surface with conventional microscopy techniques, when most of the micromechanisms in SMAs are 3-D, out-of-plane and sensitive to internal constraints."

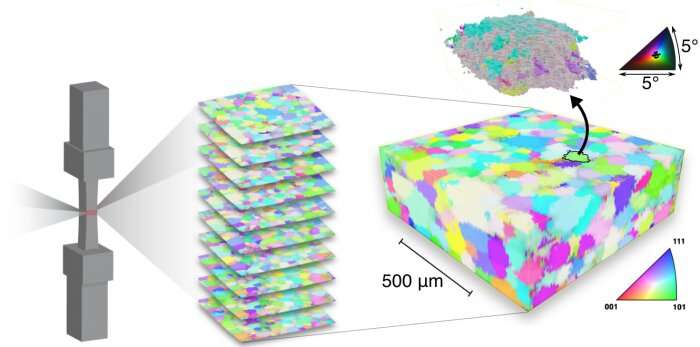

To bridge that gap, Bucsek and her fellow researchers put nickel titanium—the most widely used and available SMA—under some of the most powerful 3-D microscopes available today, located at the Cornell High Energy Synchrotron Source (CHESS) at Cornell University in upstate New York.

Specifically, she used near-field and far-field high-energy diffraction microscopy (HEDM), which fall under the umbrella of 3-D X-Ray Diffraction techniques, allowing her to visualize the material's interior microstructure in three dimensions while it's responding in real time.

"Even though HEDM has been developed at CHESS and other synchrotrons around the world for over a decade now, the procedures for applying HEDM to studying advanced materials with features like low-symmetry phase mixtures and large crystal size disparities were essentially nonexistent," Bucsek said. "As a result, each of these three experiments required the development of novel experimental, data analysis and data visualization techniques to extract the desired information. Many of the results were surprising, shedding light on decades-old areas of contention in SMA micromechanics."

In SMAs, it is often the high-symmetry phase called "austenite" that is stable at a higher temperature, but if enough stress is applied or the temperature is decreased, it will phase transform to a low-symmetry phase called "martensite."

The first paper, "Measuring stress-induced martensite microstructures using far-field high-energy diffraction microscopy," published in September in Acta Crystallographica Section A: Foundations and Advances, looked to predict the specific variety of martensite that would form.

"Using this approach, we found that martensite microstructures within SMAs strongly violated the predictions of the maximum transformation work criterion, showing that the application of the widely accepted maximum transformation work criterion needs to be modified for cases where SMAs may have engineering-grade microstructure features and defects," Bucsek said.

The second experiment tackled load-induced twin rearrangement, or martensite reorientation, a reversible deformation mechanism by which materials can accommodate large loads and deformations without damage through rearrangements of crystallographic twins.

The paper, "Ferroelastic twin reorientation mechanisms in shape memory alloys elucidated with 3-D X-ray microscopy," is set to be published in March in Journal of the Mechanics and Physics of Solids.

"A specific sequence of twin rearrangement micromechanisms occurs inside macroscopic deformation bands as they propagate through the microstructure, and we showed that the strain localization inside these bands causes the lattice to curve up to 15 degrees, which has important implications on elastic strain, resolved shear stress, and maximizing the twin rearrangement," Bucsek said "These findings will guide future researchers in employing twin rearrangement in novel multiferroic technologies."

Solid-state actuation is one of the most important applications of SMAs, used in a number of nanoelectromechanical and microelectromechanical systems, biomedical, active damping and aerospace actuation systems.

The target of the final experiment was a phenomenon in which special high-angle grain boundaries emerge inside austenite grains when SMAs are actuated. During actuation, phase transformation from austenite to martensite then back to austenite is induced by heating, cooling and then reheating the SMA while under a constant load.

The paper, "3-D in situ characterization of phase transformation induced austenite grain refinement in nickel-titanium," will appear in March in Scripta Materialia.

"Using electron microscopy, it has been observed that the austenite can exhibit large rotations when the sample is reheated, which is detrimental to both work output and fatigue. However, because of the small sample sizes required for electron microscopy, these rotations were observed very inconsistently, appearing but then not appearing under the same loading conditions, or appearing after a few cycles but then not appearing after a few thousand cycles," Bucsek said. "Our results showed that these grain rotations can occur after just one cycle in moderate condition. But because of the low volume and heterogenous dispersion of the rotations, a bulk volume is required to observe them."

Funding for Bucsek's research came from the National Science Foundation (NSF) Graduate Research Fellowship, as well as the 2015 NSF CAREER Award of her Ph.D. advisor and co-author, Aaron Stebner, Rowlinson Associate Professor of Mechanical Engineering at Mines. Additional funding to use the high-performance computers needed to analyze the data came from the NSF XSEDE program.

"Dr. Bucsek's thesis work documented in these articles shows the importance of using 3-D techniques to study the 3-D structure of materials. She was able to observe and understand mechanisms that have been postulated and debated for over 50 years for the first time," Stebner said. "The biggest hindrance to adopting new materials, like most technologies, is fear of the unknown. Such understanding will undoubtedly lead to wider acceptance and application of these miraculous materials, as it improves our confidence in developing means to certify and qualify them."

The operation of the Cornell High Energy Synchrotron Source, which was used to perform the X-ray microscopy measurements, was also provided by NSF.

"Throughout her thesis work, Dr. Bucsek developed new, creative ways to apply HEDM methods to the study of shape memory alloy systems," said Darren Pagan, staff scientist at CHESS. "Her ability to overcome challenges associated with data processing and interpretation enabled new insights to be gained into the micromechanics of shape memory alloy deformation."

More information: A.N. Bucsek et al, Three-dimensional in situ characterization of phase transformation induced austenite grain refinement in nickel-titanium, Scripta Materialia (2019). DOI: 10.1016/j.scriptamat.2018.11.043

A.N. Bucsek et al. Ferroelastic twin reorientation mechanisms in shape memory alloys elucidated with 3D X-ray microscopy, Journal of the Mechanics and Physics of Solids (2018). DOI: 10.1016/j.jmps.2018.12.003

Ashley Nicole Bucsek et al. Measuring stress-induced martensite microstructures using far-field high-energy diffraction microscopy, Acta Crystallographica Section A Foundations and Advances (2018). DOI: 10.1107/S205327331800880X

Journal information: Scripta Materialia

Provided by Colorado School of Mines