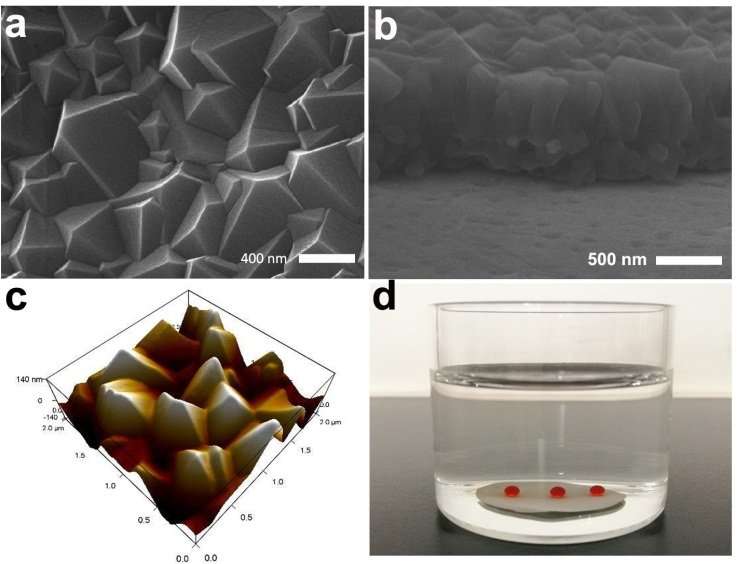

(a, b) SEM images and (c) of AFM image ZIF-8-coated mesh membrane; (d) The photograph of several oil droplets on the ZIF-8-coated mesh membrane. Credit: ©Science China Press

Frequent oil spills during oil transportation have become a critical global environmental and economic problem. Traditional oil-water separation technologies, including centrifugation, filtration, dissolved air flotation, oil skimmers and adsorption, have low efficiency and consume large amounts of energy during complex separation processes.

Membrane separation is a promising and economical approach to tackle energy and environmental challenges. Inspired by the anti-wetting behavior of an oil droplet on fish scales in water, researchers have developed underwater superoleophobic materials in recent years. However, some organic polymer membranes lose oil-water separation capacity at high temperature or exposure to organic solvents. Additionally, producing most inorganic membranes entails complex preparation processes.

In order to solve these problems, Ming Xue and co-workers from Jilin University, China, have introduced a micro/nanostructure into a MOF membrane to improve the water/oil separation efficiency. Their results are published in Science China Materials.

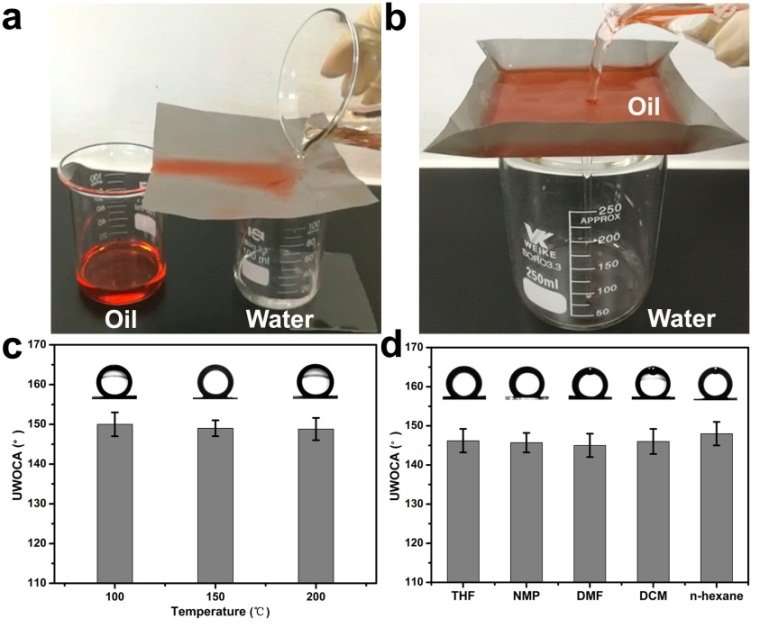

(a, b) Photographs of the oil-water separation process using the ZIF-8-coated mesh membrane; (c, d) Underwater oil contact angles (UWOCAs) of the ZIF-8-coated mesh membrane after heating treatment under different temperatures and immersing in various organic solvents. Credit: ©Science China Press

"We successfully constructed a ZIF-8-coated mesh membrane with excellent oil-water separation performance by simply immersing the mesh in a precursor solution at room temperature and atmospheric pressure," said Prof. Xue. "The membrane shows underwater superoleophobic properties, which is attributed to the micro and nanostructure on the surface of the ZIF-8-coated membrane. The water phase imbibes into the micro and nano hierarchical structure of membrane surface, forming a barrier layer, which allows the water phase to pass through the membrane via gravity quickly, and rejects the oil phase. This is the separation mechanism."

This MOF membrane exhibits excellent separation efficiency over 99.99 percent for various oil-water mixtures with the residual oil content in the collected water less than 4 ppm. It also shows a remarkable water flux as high as 10,2000 L/m2h and higher oil intrusion pressure of 6400 Pa. Regarding stability, Xue said, "this membrane displays outstanding stability under high temperature (200°C) and when exposed to various organic solvents (tetrahydrofuran (THF), N, N'-dimethylformamide (DMF), N-methyl-2-pyrrolidone (NMP), dichloromethane (DCM) and n-hexane) immersion."

"More importantly," he added, "based on its facile fabrication method and the readily available and cheap materials, this kind of MOF membrane can be easily enlarged, and able to treat a large amount of oil-water mixture."

More information: Mingqiu Song et al, A stable ZIF-8-coated mesh membrane with micro-/nano architectures produced by a facile fabrication method for high-efficiency oil-water separation, Science China Materials (2018). DOI: 10.1007/s40843-018-9345-3

Provided by Science China Press