At last, a simple 3-D printer for metal

Used to produce three-dimensional objects of almost any type, across a range of industries, including healthcare, aviation and engineering, 3-D printed materials have come of age during the last decade. Research published in the journal Materials Today demonstrates a new approach to 3-D printing to fuse metallic filaments made from metallic glass into metallic objects.

Jan Schroers, Professor of Mechanical Engineering and Materials Science at Yale University and Desktop Metal, Inc., in Burlington, Massachusetts, USA, along with colleagues point out that 3-D printing of thermoplastics is highly advanced, but the 3-D printing of metals is still challenging and limited. The reason being that metals generally don't exist in a state that they can be readily extruded.

"We have shown theoretically in this work that we can use a range of other bulk metallic glasses and are working on making the process more practical- and commercially-usable to make 3-D printing of metals as easy and practical as the 3-D printing of thermoplastics," said Prof. Schroers.

Unlike conventional metals, bulk metallic glasses (BMGs) have a super-cooled liquid region in their thermodynamic profile and are able to undergo continuous softening upon heating—a phenomenon that is present in thermoplastics, but not conventional metals. Prof. Schroers and colleagues have thus shown that BMGs can be used in 3-D printing to generate solid, high-strength metal components under ambient conditions of the kind used in thermoplastic 3-D printing.

The new work could side-step the obvious compromises in choosing thermoplastic components over metal components, or vice-versa, for a range of materials and engineering applications. Additive manufacturing of metal components has been developed previously, where a powder bed fusion process is used, however this exploits a highly-localized heating source, and then solidification of a powdered metal shaped into the desired structure. This approach is costly and complicated and requires unwieldy support structures that are not distorted by the high temperatures of the fabrication process.

The approach taken by Prof. Schroers and colleagues simplifies additive manufacturing of metallic components by exploiting the unique-amongst-metals softening behavior of BMGs. Paired with this plastic like characteristics are high strength and elastic limits, high fracture toughness, and high corrosion resistance. The team has focused on a BMG made from zirconium, titanium, copper, nickel and beryllium, with alloy formula: Zr44Ti11Cu10Ni10Be25. This is a well-characterized and readily available BMG material.

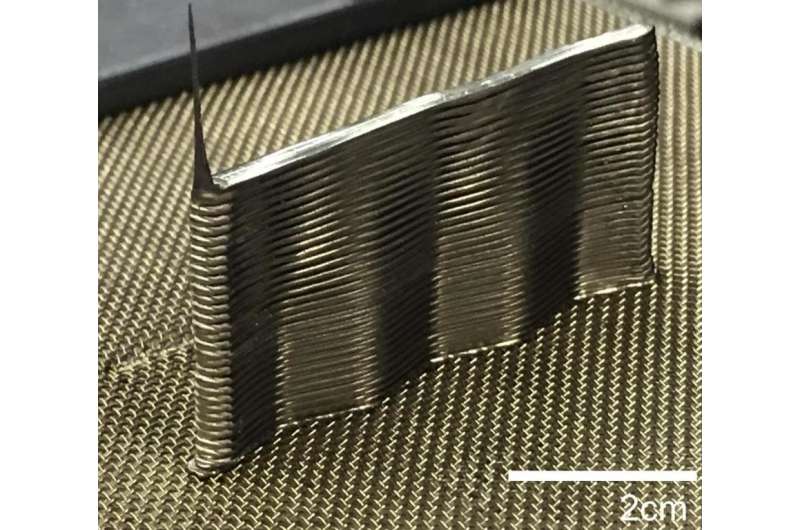

The team used amorphous rods of 1 millimeter (mm) diameter and of 700mm length. An extrusion temperate of 460 degrees Celsius is used and an extrusion force of 10 to 1,000 Newtons to force the softened fibers through a 0.5mm diameter nozzle. The fibers are then extruded into a 400°C stainless steel mesh wherein crystallization does not occur until at least a day has passed, before a robotically controlled extrusion can be carried out to create the desired object.

When asked what challenges remain toward making BMG 3-D printing a wide-spread technique, Prof. Schroers added, "In order to widely use BMG 3-D printing, practical BMG feedstock available for a broad range of BMGs has to be made available. To use the fused filament fabrication commercially, layer-to-layer bonding has to be more reliable and consistent."

More information: Michael A. Gibson et al. 3D printing metals like thermoplastics: Fused filament fabrication of metallic glasses, Materials Today (2018). DOI: 10.1016/j.mattod.2018.07.001

Journal information: Materials Today

Provided by Elsevier