September 28, 2018 feature

Engineering 3-D mesostructures with mechanically active materials

Microelectromechanical systems (MEMS) have expansive applications in biotechnology and advanced engineering with growing interest in materials science and engineering due to their potential in emerging systems. Existing techniques have enabled applications in cell mechanobiology, high-precision mass sensing, microfluidics and in energy harvesting. Projected technical implications broadly include constructing precision-sensing MEMS, tissue scaffolds that mimic the principles of mechanobiology, and energy-harvesting applications that can operate on supported broad bandwidths. At present, devices (microsensors and MEMS) are fabricated using manufacturing methods of the semiconductor industry—specifically, two-dimensional (2-D) lithographic etching—with mechanical and electric components in planar configuration.

Extending the 2-D MEMS to the third dimension can allow broader applications and is an active area of ongoing research. Dynamic actuation is critically important in the design and development of bioMEMS, modulators and radiofrequency switches. Thin-film piezoelectric materials presently form the basis of actuators to produce fast switching at small driving voltages, in compact/lightweight configurations. The present focus in microscale mechanical engineering is to transfer such piezoelectric components into complex 3-D frameworks.

In a recent study, Xin Ning and co-workers introduced strategies for the guided assembly and integration of heterogeneous materials to form complex 3-D microscale mechanical frameworks. The work combined multiple, independent piezoelectric thin-film actuators for vibratory excitation and precise control. To enable geometric transformation from 2-D to 3-D, the approach combined transfer printing as a scheme for materials integration, alongside structural buckling. The resulting designs on planar or curvilinear surfaces ranged from simple, symmetric layouts to complex hierarchical configurations. Experimental and computational studies systematically revealed underlying characteristics and capability of selectively exciting targeted vibrational modes that can simultaneously measure the viscosity and density of fluids. This offers significant potential for applications in biomedical engineering. Now published in Science Advances, the results serve as a foundation for an unusual class of mechanically active 3-D mesostructures with broad scope for advanced applications.

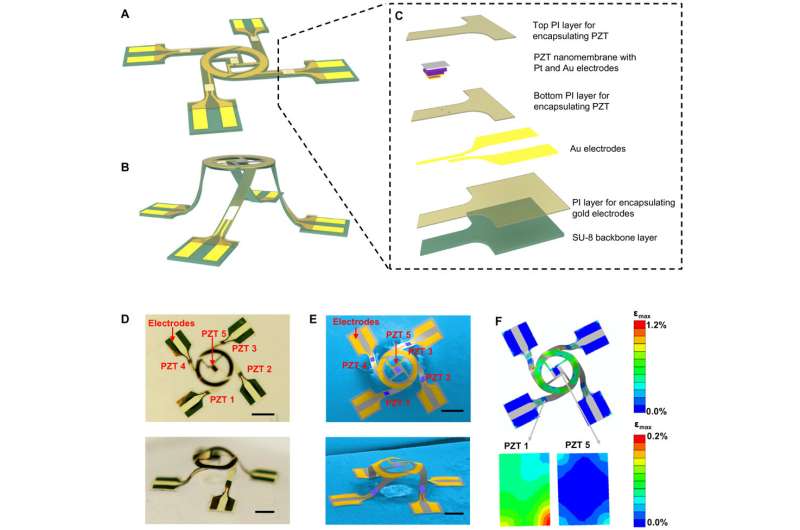

The scientists used cutting-edge methods in transfer printing to integrate ultrathin piezoelectric films and ductile metals into polymer layers that were lithographically patterned into 2-D geometries. Controlled mechanical buckling transformed the 2-D multifunctional material structures into well-defined 3-D architectures. The 3-D mechanical responses were first modeled with finite element analysis (FEA) to select structural topologies and actuator locations to engineer controlled dynamics with displacements and distributions.

In the study, the authors designed and assembled the 3-D mechanical mesostructures beginning with formation of 2-D precursor structures. The method integrated multiple functional materials via processes in microfabrication and transfer printing. The system comprised a photodefinable epoxy framework with patterned thin films of Pb(Zr0.52Ti0.48)O3 (PZT) as mechanical actuators and gold (Au) as electrodes and electrical interconnectors. Layers of polyimide (PI) encapsulated the system except in selected areas. These areas bonded the 3-D structure to the underlying elastomeric structure as contact sites for electrical probing. The authors used a mechanically guided process of compressive buckling to transform the 2-D precursor into a final 3-D architecture by releasing the pre-strain in the underlying elastomeric substrate. The optical and SEM images detailed the position of five independent PZT actuators; one at the center and four on the supporting legs.

The quantitative FEA conducted in the study served as a measure to optimize the locations of the PZT and metal layers, ensuring architectural integrity during compressive buckling. The predicted 3-D configuration agreed with the experimental observation. The schemes developed in the study to fabricate active mesostructures provided access to diverse classes of unique 3-D microscale architectures.

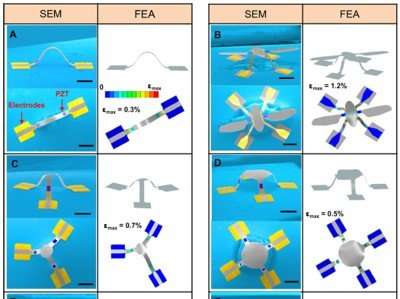

Variations to the complex geometry layouts enabled the formation of unique 3-D microscale architectures. The microarchitectures included complex geometries resembling insects with wings and four legs, asymmetric 3-D geometries illustrated with a pyramid truss and a table structure. Each of these geometries were computed by FEA that excellently matched the experimental observation, demonstrating precision of the microfabrication process.

The vibratory behavior of 3-D mesostructures excited by PZT microactuators were observed for all geometries designed in the study. The PZT microactuators were placed strategically in regions of interest on the 3-D geometries to control dynamic behavior and resonant modes.

The strategic 3-D designs created in the study introduced two qualitatively different and well-separated resonant modes to the mesostructures. Such resonant frequencies were able to decouple the sensitivities of viscosity and density of a fluid as two separate measurable quantities. The 3-D mesostructures optimized in the study were able to separately measure the viscosity and density of a variety of Newtonian fluids. This contrasted with conventional 2-D resonators that were sensitive to both viscosity and density parameters in a coupled manner, unable to precisely differentiate the two parameters therefore. Usually, to accurately measure high-frequency vibrations and quality factors in highly viscous fluids, sophisticated experimental apparatus such as doppler vibrometers or precisely calibrated strain sensors are used with their accompanying challenges, the 3-D mesostructures present a simpler method with high precision.

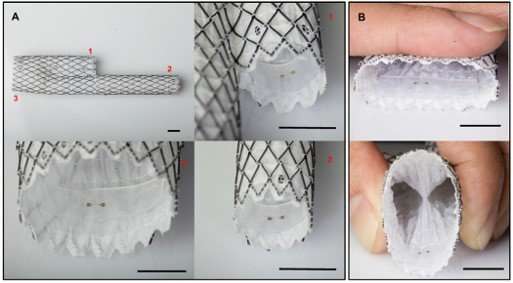

Collective measurement capabilities of the 3-D structures indicated their broad utility to investigate complex fluids in healthcare and industry. Such 3-D structures can be integrated onto the surfaces of medical devices as inbuilt sensors due to their compliance. For instance, the authors recommend the integration of mesostructures on a cardiovascular stent (a device used to facilitate unconstructed blood flow in patients with atherosclerotic/deformed arteries) to precisely measure hemodynamics in the stent environment.

The capacity to integrate functional, high-performance piezoelectric materials into complex 3-D architectures for unusual classes of materials with active, high-precision and programmable function were demonstrated. The ubiquity of the materials integrated in the study can facilitate the development of 3-D MEMS and related technologies for advanced sensing applications within multidisciplinary fields.

More information: Xin Ning et al. Mechanically active materials in three-dimensional mesostructures, Science Advances (2018). DOI: 10.1126/sciadv.aat8313

Journal information: Science Advances

© 2018 Phys.org