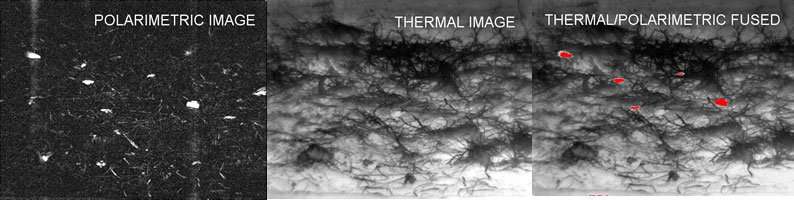

Researchers demonstrate an example of human identification using conventional and polarimetric thermal cameras. The thermal polarimetric image allows for fine facial details to emerge, researchers said. Credit: US Army

Researchers at the U.S. Army Research Laboratory have developed a new type of thermal imaging camera that allows soldiers to see hidden objects that were previously undetectable.

Dr. Kristan Gurton, an experimental physicist in the Computational and Information Sciences Directorate, and Dr. Sean Hu, an electronics engineer in the Sensors and Electron Devices Directorate, are leading this effort for the laboratory.

According to Gurton, all objects that have a non-zero temperature emit thermal radiation in the infrared portion of the spectrum, and the intensity of that radiation is proportional to its temperature.

Thermal radiation is always present in the environment regardless of whether it's day or night, which is why the Army uses thermal cameras to see objects that are often hidden in the dark.

However, in addition to the intensity of the infrared radiation, there is another characteristic of light that is often ignored when it comes to imaging: polarization state.

"Researchers have known for about 30 years that man-made objects emit thermal radiation that is partially polarized, for example, trucks, aircraft, buildings, vehicles, etc., and that natural objects like grass, soil, trees and bushes tend to emit thermal radiation that exhibits very little polarization," Gurton said. "We have been developing, with the help of the private sector, a special type of thermal camera that can record imagery that is based solely on the polarization state of the light rather than the intensity. This additional polarimetric information will allow Soldiers to see hidden objects that were previously not visible when using conventional thermal cameras."

Gurton is pursuing the development of the camera hardware, while Hu is working on software designed to best exploit the additional information thermal polarimetric imaging provides.

Army researchers show an example of human identification using conventional and polarimetric thermal cameras. The thermal polarimetric image allows for fine facial details to emerge. Credit: US Army

According to Gurton, while the Army has always had a robust conventional thermal imaging program, his efforts are a natural progression attempting to advance the technology further.

"Soldier-specific applications that we have been investigating include the detection of hidden trip-wires and booby-traps, enhanced ability to see camouflaged targets, identification of buried land-mines and improvised explosive devices, and enhanced targeting and tracking of missiles, mortars, unmanned aerial vehicles and other airborne threats," Gurton said.

The team's most recent and exciting discovery involves the ability to detect and identify specific human subjects during complete darkness.

"Prior to our research at ARL, the only way to view humans at night was to use conventional thermal imaging," Gurton said. "Unfortunately, such imagery is plagued by a "ghosting" effect in which detailed facial features required for human identification are lost. However, when polarization information is included in the thermal image, i.e., a thermal polarimetric image, fine facial details emerge, which allows facial recognition algorithms to be applied."

Due to the technical difficulty in building thermal polarimetric camera systems, very little research had been conducted prior to Gurton and Hu's involvement studying this novel phenomena starting in 2005.

"Our primary goal was to develop a new type of camera system that could detect objects that were difficult, or impossible, to see using current state-of-the-art thermal cameras," Gurton said.

"We are working with the private sector on a two-prong approach in which both research grade and ruggedized commercial grade polarimetric cameras are being developed," Gurton said. "It's our hope that in the future, all deployed Department of Defense thermal imaging systems will have a polarimetric ability that can be implemented with a simple press of a button."

Scientists show how identification of hidden booby-traps and trip wires using conventional and polarimetric thermal cameras. Thermal polarimetric image allows for finer details to emerge. Credit: US Army

The researchers' primary private sector partner dealing with polarimetric imaging is Polaris Sensor Technologies, Inc., in Huntsville, Alabama.

The relationship between ARL and Polaris has been formalized through the Army's Small Business Innovation Research program.

"The goal of the relationship with Polaris is to overcome all of the technical issues that plagued prior attempts at a new thermal imaging camera, and we have been successful ever since implementing this new technology," Gurton said.

"Shortly after I was hired at ARL as an experimental physicist in 1998, I inherited a bunch of old 1980s vintage thermal cameras from a retired scientist," Gurton said. "I became interested in studying thermal radiance and I wanted to do something that was new and novel, and that had not been exhaustively studied. I found several old technical papers from the 1980s describing failed attempts trying to implement thermal polarimetric imaging."

When Gurton spoke to the various engineers in both the private sector and DOD who were involved in the prior efforts, they stated the issues that limited past attempts were due to overly complex design, which led to significant pixel mis-registration errors, which rendered the systems useless.

"We took those lessons learned and I issued my first Small Business Innovation Research contract with Dr. David Chenault of SY Technologies, now president at Polaris Sensor Technologies," Gurton said.

The main problems with prior efforts were twofold. First, early efforts were far too complex, she said.

"Early on, researchers attempted to place micro-polarizers on individual micron-size pixels of the infrared focal-plane-array, or FPA," Gurton said. "Both the FPAs and micro-pixel polarizers technology in the 80s and 90s were fairly unsophisticated. During my first contract, I stressed a KISS approach, for example, keep it simple stupid, and I insisted that competing companies avoid the so-called micro-pixel approach and propose very simple concepts in order to produce a calibrated research-grade thermal polarimetric camera system that would actually work. For this new design, we settled on a simple rotating element approach, which is still the gold standard today."

The second problem involved the mis-registration of images that plagued earlier systems, she said.

"In general, a polarimetric image is actually a subtraction of two perfectly registered images," Gurton said. "If the two images are slightly mis-registered, it won't work. We set a goal of a minimum degree of miss registration of 1/10 of a pixel that had to be met. Currently, Polaris Sensor Technologies, Inc., routinely develop systems that have less than 1/20 of pixel mis-registration."

Gurton said she believes that the future for commercialization will involve implementing the earlier micro-pixel FPA approach that proved so difficult, and is still extremely technically challenging.

In spite of the difficulties, Polaris has successfully produced a micro-pixel based camera using uncooled microbolometers and is demonstrating it in Army field tests and on drones.

In terms of next steps to bring this technology to fruition, Gurton and the other researchers are actively working to miniaturize the camera platform and make the systems more affordable.

Provided by The Army Research Laboratory