Credit: American Chemical Society

Sharks are often the subject of TV specials or news stories focusing on their attacks on humans. But scientists are finding that sharks could inspire a new type of surface that would attack bacteria, helping humans instead of hurting them. As reported in ACS Applied Materials & Interfaces, researchers have designed a coating that is infused with antimicrobial agents and has the patterned diamond-like texture of shark skin.

Fighting bacteria is an ongoing battle, resulting in more than 2 million infections and 23,000 deaths in the U.S. every year, according to the U.S. Centers for Disease Control and Prevention. As a result of overusing antibiotics, bacterial resistance to these drugs is on the rise. Patients in hospitals who are already battling illnesses or have compromised immune systems are especially at risk of developing infections just by touching contaminated bedrails and door knobs. Scientists have been developing coatings for these high-touch surfaces to fight the spread and growth of microbes. For example, Sharklet AF is a coating designed to mimic a shark's skin, and it reduces the ability of bacteria to adhere to surfaces. But long-term use will result in bacteria accumulation. James J. Watkins, Jessica D. Schiffman and colleagues wanted to see if adding titanium dioxide (TiO2) nanoparticles, which are antibacterial, to a shark skin material would efficiently fight off microbes.

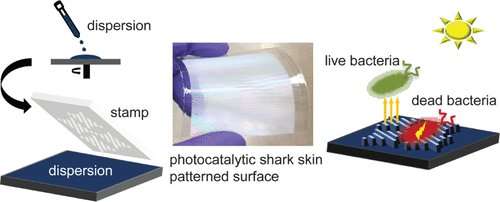

The team printed their own shark skin surfaces with polymer and ceramic composites, and added titanium dioxide nanoparticles to them. The shark skin surface without nanoparticles reduced the attachment of E. coli by 70 percent compared to smooth films. But shark skin surfaces with TiO2 nanoparticles exposed to UV light for one hour killed off over 95 percent of E. coli and 80 percent of Staphylococcus aureus. The group says the fabrication method could be scaled up for mass production.

More information: Feyza Dundar Arisoy et al, Bioinspired Photocatalytic Shark-Skin Surfaces with Antibacterial and Antifouling Activity via Nanoimprint Lithography, ACS Applied Materials & Interfaces (2018). DOI: 10.1021/acsami.8b05066

Abstract

By combining antifouling shark-skin patterns with antibacterial titanium dioxide (TiO2) nanoparticles (NPs), we present a simple route toward producing durable multifunctional surfaces that decrease microbial attachment and inactivate attached microorganisms. Norland Optical Adhesive, a UV-crosslinkable adhesive material, was loaded with 0, 10, or 50 wt % TiO2 NPs from which shark-skin microstructures were imprinted using solvent-assisted soft nanoimprint lithography on a poly(ethylene terephthalate) (PET) substrate. To obtain coatings with an exceptional durability and an even higher concentration of TiO2 NPs, a solution containing 90 wt % TiO2 NPs and 10 wt % tetraethyl orthosilicate was prepared. These ceramic shark-skin-patterned surfaces were fabricated on a PET substrate and were quickly cured, requiring only 10 s of near infrared (NIR) irradiation. The water contact angle and the mechanical, antibacterial, and antifouling characteristics of the shark-skin-patterned surfaces were investigated as a function of TiO2 composition. Introducing TiO2 NPs increased the contact angle hysteresis from 30 to 100° on shark-skin surfaces. The hardness and modulus of the films were dramatically increased from 0.28 and 4.8 to 0.49 and 16 GPa, respectively, by creating ceramic shark-skin surfaces with 90 wt % TiO2 NPs. The photocatalytic shark-skin-patterned surfaces reduced the attachment of Escherichia coli by ∼70% compared with smooth films with the same chemical composition. By incorporating as low as 10 wt % TiO2 NPs into the chemical matrix, over 95% E. coli and up to 80% Staphylococcus aureus were inactivated within 1 h UV light exposure because of the photocatalytic properties of TiO2. The photocatalytic shark-skin-patterned surfaces presented here were fabricated using a solution-processable and roll-to-roll compatible technique, enabling the production of large-area high-performance coatings that repel and inactivate bacteria.

Journal information: ACS Applied Materials and Interfaces

Provided by American Chemical Society