Material scientists shape the surface of tiny, curved carbon fibres using laser structuring

The surfaces of materials can have an enormous influence on their function. If the external properties are changed, this also expands the range of possible applications. This is why materials scientists at Friedrich Schiller University Jena (Germany) are researching how they can tailor the surfaces of different materials using laser technology. They are mainly focusing on laser-induced periodic surface structures, also known as LIPSS. This method can be used to create particularly tiny structures. They report on a very special success in this field in the internationally renowned trade journal Carbon.

"When a surface is irradiated with a femtosecond laser—a laser with very short and intense light pulses—characteristic structures are formed at the point where the laser beam hits the surface," explains Dr. Stephan Gräf from the Otto Schott Institute of Materials Research at Jena University. "Interference effects at this focal point create the LIPSS." These structures are much smaller than those reached using normal laser structuring because a laser beam cannot be focused as small as desired. The size of the structures depends, among other parameters, on the laser intensity and the laser wavelength used. Based on a careful adjustment of the laser beam parameters, the structures can be fabricated in an almost tailor-made manner. Large areas of the periodic pattern can be implemented by scanning the entire surface with the laser beam.

Now even on strongly curved surfaces

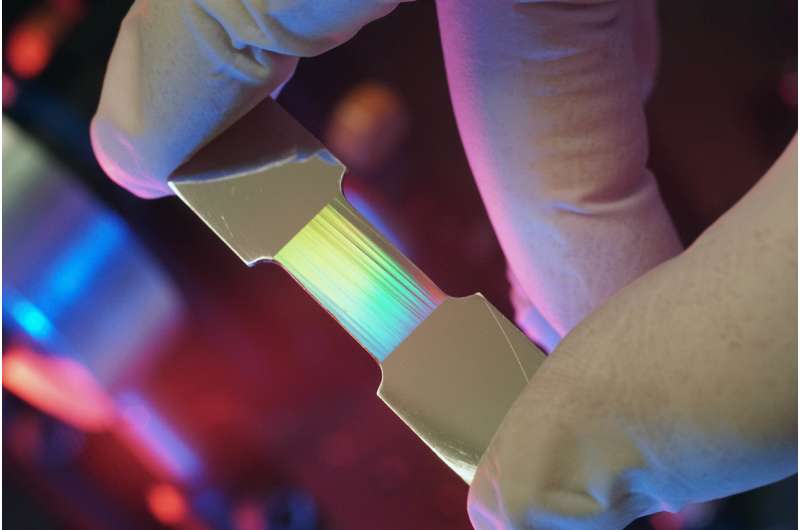

Generally, the method works on many different classes of materials; however, up to now it could only be applied to flat surfaces. The Jena scientists have now succeeded in producing laser-induced periodic structures on strongly curved surfaces. "We have realized LIPSS on the surface of about ten micrometre thin carbon fibres—their diameter is hardly larger than the structures themselves," says Gräf. "Furthermore, we were able to superimpose different types of structures and therefore to hierarchically shape the surface."

These current findings will provide completely new possibilities in practical applications. For instance, carbon fibres are embedded in other materials such as polymers for manufacturing composite materials. To improve the strength of composite materials, they have, until now, been treated with chemicals, for example. Thanks to LIPSS, their surface topography can now be specifically altered so that anchoring between polymer and embedded fibres can take place.

More durable materials

In addition, the structures act as an optical diffraction grating. They allow the reflection and absorption behaviour of light on surfaces to be changed in a specific manner. The same also applies to the diffraction of light. Based on so-called 'structural colours," it is possible to selectively design surfaces in colour. As a result, laser-induced periodic surface structures gain increasing interest for optical applications.

And LIPSS also positively influences the durability of materials: "By changing the surface topography, the friction coefficient can be reduced and wear can therefore be prevented," says the materials scientist Gräf from Jena University. "For example, more durable implants could be developed in this way." In addition, the wetting properties of materials can be changed in this way. They can therefore be designed to be more hydrophobic or hydrophilic.

More information: Clemens Kunz et al, Large-area fabrication of low- and high-spatial-frequency laser-induced periodic surface structures on carbon fibers, Carbon (2018). DOI: 10.1016/j.carbon.2018.03.035

Journal information: Carbon

Provided by Friedrich Schiller University of Jena