Credit: American Chemical Society

Although the U.S and other countries have banned or restricted the use of bisphenol A (BPA) because of environmental and health concerns, it is still used in thermally printed receipts and labels. Now researchers report in a study in the ACS journal Industrial & Engineering Chemistry Research that they have developed potentially safer polymers that could replace BPA for printed papers.

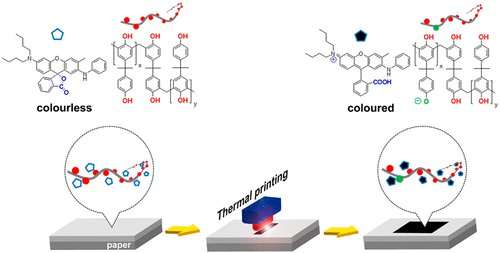

Thermal papers are used for cash register receipts, tickets and labels because they are cheap, easy to use and reliable. For thermal paper to work in printing, it is impregnated with two molecules, a dye and a color developer. The color developer, BPA, causes the paper to react with the dye and change colors when heated. While BPA has many advantages, it can potentially cause various health effects by moving through biological membranes, interfering with hormones and harming the nervous and reproductive systems. Manufacturers have turned to polymeric materials as a potential substitute because they are large and cannot easily move through membranes. Some of polymers tested thus far have had similar properties to BPA, but the developer results have been mediocre. Byeong-Kwan An, Hyun-Jin Kwon and Kang-Hoon-Choi wanted to see if they could produce an alternative developer that would perform as well as BPA.

The researchers focused on phenolic resin polymers because of they are easy to make, inexpensive and will react with the dyes in thermal paper. The team prepared different variations of the polymers and examined their thermal properties, stability and ability to react with the dye on paper. Out of those tested, BPAF-N-type (BPA-formaldehyde novolac) polymers fit the bill—they were stable under high temperatures and reacted with the dye just as well as BPA. One was more suited to general-purpose applications, whereas two of them were more appropriate for papers that need to be used in heated environments.

More information: Kang-Hoon Choi et al. Synthesis and Developing Properties of Functional Phenolic Polymers for Ecofriendly Thermal Papers, Industrial & Engineering Chemistry Research (2017). DOI: 10.1021/acs.iecr.7b03129

Abstract

Owing to the multiple potential health risks caused by exposure to BPA and the strengthened regulation of BPA-containing thermal papers, much concern has been raised recently regarding a BPA-type color developer in thermal papers. However, few efforts have so far been focused on the development of safer alternative materials to BPA. In this study, we examined the use of polymeric materials as a safer replacement for BPA in thermal papers. For this objective, a series of phenolic polymers, phenol-formaldehyde novolac and resole (PF-N and PF-R) and BPA-formaldehyde novolac and resole (BPAF-N and BPAF-R), were prepared. Among these polymers, a BPAF-N-type polymer was determined to be the most appropriate candidate for a developer material in thermal papers. Through printing tests of the prepared thermal papers, it was found that BPAF-N_8 polymer has a high static sensitivity and dark contrast of thermal papers similar to those of BPA, whereas the BPAF-N_16 and BPAF-N_30 polymers have lower static sensitivities than BPFA-N_8 and BPA.

Journal information: Industrial & Engineering Chemistry Research

Provided by American Chemical Society