Credit: American Chemical Society

Someday, left-over toner in discarded printer cartridges could have a second life as bridge or building components instead of as trash, wasting away in landfills and potentially harming the environment. One group reports in ACS Sustainable Chemistry & Engineering that they have devised a method to recycle the residual powder in "empty" cartridges into iron using temperatures that are compatible with existing industrial processes.

Electronic waste is a broad category that encompasses everything from computers and televisions to ink cartridges and refrigerators. According to the European Toner and Inkjet Remanufacturers Association, 500 million cartridges out of the estimated 1.1 billion sold each year end up in landfills around the world. These "empty" cartridges can contain up to 8 percent of unused residual powder by weight and could leach compounds into the soil and underground water sources. In an attempt to reuse this electronic waste, researchers have transformed this substance into oils, gases and even an ingredient in asphalt. Now, Vaibhav Gaikwad and colleagues wanted to develop a brand-new way to re-use residual toner.

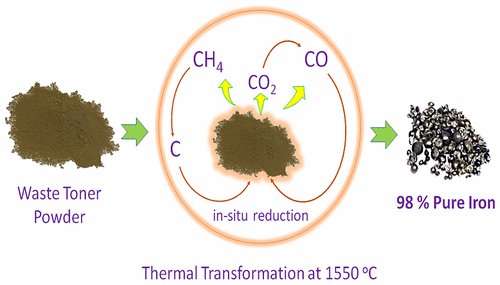

The researchers put toner powder in a furnace, heating it to 1,550 °C. This process converted the inherent iron oxide to a product that was 98 percent pure iron using the polymer resins within the toner powder as a source of carbon. The researchers say that this method would be ideal for industrial applications because iron and steel are typically made at this temperature. In addition, heating the powder at such a high temperature prevents toxic side products from forming, providing an environmentally friendly way to recycle residual toner.

More information: Vaibhav Gaikwad et al. Thermal Transformation of Waste Toner Powder into a Value-Added Ferrous Resource, ACS Sustainable Chemistry & Engineering (2017). DOI: 10.1021/acssuschemeng.7b02875

Abstract

This paper describes the development of a thermal transformation process to recycle waste toner powder in a sustainable and environmentally friendly manner. The process leverages high-temperature reactions and the morphology and chemical composition of waste toner powder, mainly the iron oxide and carbon content, by utilizing the gases evolved during the thermal transformation as an in situ source of carbon to convert the waste toner powder into 98% pure iron. A temperature of 1550 °C was employed in the present study to ensure the complete transformation of waste toner powder to iron and also because of its practical relevance to operating conditions encountered in metal manufacturing and processing industries. The process delivers an iron recovery of 81.6%. X-ray diffraction, scanning electron microscopy–energy-dispersive spectroscopy, and inductively coupled plasma optical emission spectroscopy analyses were employed to confirm the composition of the metallic product. GC–MS analysis was utilized to monitor gaseous aromatic compounds during the thermal degradation studies of the waste toner powder, and none were detected above 1200 °C. In addition, this paper presents a comprehensive characterization of the waste toner powder and resultant products using various analytical techniques, a kinetic study of the thermal decomposition of waste toner powder, and a pelletization technique to overcome its material handling hazards.

Provided by American Chemical Society