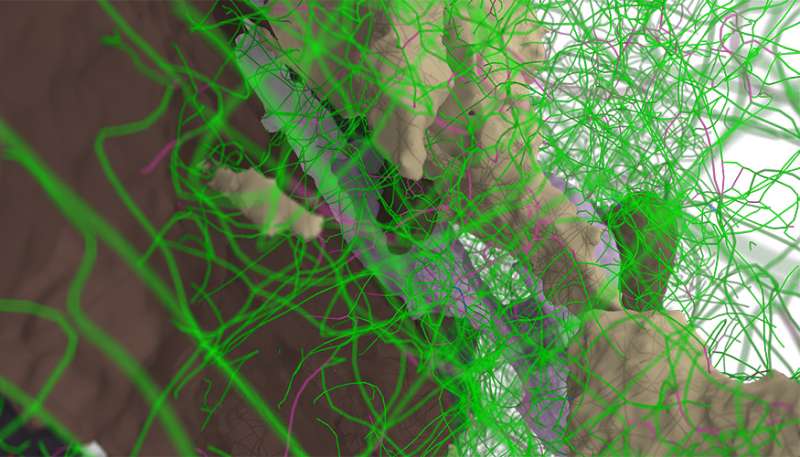

Tantalum crystal can flow like a viscous fluid while remaining a stiff and strong metal and retaining its ordered lattice structure. This snapshot depicts a dense network of lattice defects developing in the flowing crystal. Credit: Lawrence Livermore National Laboratory

Lawrence Livermore National Laboratory researchers have dived down to the atomic scale to resolve every "jiggle and wiggle" of atomic motion that underlies metal strength.

In a first of its kind series of computer simulations focused on metal tantalum, the team predicted that, on reaching certain critical conditions of straining, metal plasticity (the ability to change shape under load) meets its limits. One limit is reached when crystal defects known as dislocations are no longer able to relieve mechanical loads, and another mechanism - twinning, or the sudden reorientation of the crystal lattice - is activated and takes over as the dominant mode of dynamic response.

The research appears in the Sept. 27 edition of Nature as an Advance Online Publication.

Strength and plasticity properties of a metal are defined by dislocations, line defects in the crystal lattice whose motion causes material slippage along crystal planes. The theory of crystal dislocation was first advanced in the 1930s, and much research since then has focused on dislocation interactions and their role in metal hardening, in which continued deformation increases the metal's strength (much like a blacksmith pounding on steel with a hammer). The same simulations strongly suggest that the metal cannot be strengthened forever.

Dislocation multiplication from initial sources results in development of a dense dislocation network. Crystals containing dislocations sources (loops) are subjected to uniaxial compression along the axis at a constant true straining rate. The simulation volume contains about 268 million atoms of tantalum. The video sequence progresses through extension of the initial hexagon-shaped loops, to dislocation collisions resulting in the formation of dislocation junctions, to an increasingly dense dislocation network. Green lines represent dislocations and pink lines depict junction dislocations.

"We predict that the crystal can reach an ultimate state in which it flows indefinitely after reaching its maximal strength," said Vasily Bulatov, LLNL lead author of the paper. "Ancient blacksmiths knew this intuitively because the main trick they used to strengthen their metal parts was to repeatedly hammer them from different sides, just like we do in our metal kneading simulation."

Due to severe limits on accessible length and time scales, it was long thought impossible or even unthinkable to use direct atomistic simulations to predict metal strength. Taking full advantage of LLNL's world-leading HPC facilities through a grant from the Laboratory's Computing Grand Challenge program, the team demonstrated that not only are such simulations possible, but they deliver a wealth of important observations on fundamental mechanisms of dynamic response and quantitative parameters needed to define strength models important to the Stockpile Stewardship Program. Stockpile Stewardship ensures the safety, security and reliability of nuclear weapons without testing.

Crystal microstructure evolution under straining at rate x50. In this simulation a crystal containing dislocations sources (loops) was subjected to uniaxial compression along the axis at a constant true straining rate. The simulation volume contains about 33 million atoms of tantalum. This video sequence progresses through extension of the initial loops, to nucleation of embryonic twins on screw dislocations, to rapid propagation and growth of twinning particles. The outer surfaces bounding the twins are colored light gray whereas the insides of twin particles are colored red, yellow, purple or cyan depending on each twin's rotational variant.

"We can see the crystal lattice in all details and how it changes through all stages in our metal strength simulations," Bulatov said. "A trained eye can spot defects and even characterize them to an extent just by looking at the lattice. But one's eye is easily overwhelmed by the emerging complexity of metal microstructure, which prompted us to develop precise methods to reveal crystal defects that, after we apply our techniques, leave only the defects while completely wiping out the remaining defect-less (perfect) crystal lattice.

The research team developed the first fully dynamic atomistic simulations of plastic strength response of single crystal tantalum subjected to high-rate deformation. Unlike computational approaches to strength prediction, atomistic molecular dynamics simulations rely only on an interatomic interaction potential, resolve every "jiggle and wiggle" of atomic motion and reproduce material dynamics in full atomistic detail.

“Metal kneading” at rate x25. This simulation was performed on a brick-shaped tantalum crystal. After full compression along Z axis to ¼ of its initial dimension the brick’s shape becomes 2:4:1 Another simulation starts in which the brick is compressed along now the longest Y-axis. After the second compression cycle is completed, the brick is compressed along now longest X-axis. After three compression cycles the brick recovers its initial shape 1:2:4 and one more Z-axis compression cycle is performed.

Dislocation motion in more detail. This simulation was performed from a configuration attained past yield under pre-straining. Reduction in dislocation density can be observed over the first few frames immediately following the sudden drop in the straining rate. Subsequently the network attains a dynamic steady state in which dislocation multiplication is balanced by dislocation annihilation. Taken at shorter time intervals and from a simulation that produced only relatively low dislocation density, this sequence reveals various events in the life of dislocations in greater detail than in the other videos. One can observe that dislocation motion is not steady but proceeds in a stop-and-go manner.

More information: Luis A. Zepeda-Ruiz et al. Probing the limits of metal plasticity with molecular dynamics simulations, Nature (2017). DOI: 10.1038/nature23472

Journal information: Nature

Provided by Lawrence Livermore National Laboratory