A bioplastic derived from soya protein which can absorb up to 40 times its own weight

Researchers at the University of Seville, together with experts from the University of Huelva, have obtained a natural bioplastic from soya protein that is capable of absorbing up to 40 times its own weight. This new product, which is organic and biodegradable, is environmentally friendly. The researchers are exploring its use in horticulture, specifically as a raw material from which to make agricultural nutrient dispensers.

Another of the objectives of the project was to find a material that could substitute plastics obtained from synthetic polymers, which are currently used in hygiene and sanitary products like nappies and sanitary towels. They are trying to reduce the use of artificial polymers and use another plastic that is natural and biodegradable.

To achieve the design of the new bioplastic, the researchers altered the composition of soy. This project has been carried out in collaboration with the General Service of Functional Characterisation, situated in the Centre for Research, Technology and Innovation at the University of Seville (CITIUS).

Specifically, they modified soy to make it retain a higher percentage of water. "Soya has a great capacity for absorption, which makes it an ideal material. However, we considered whether it could be classed with the super-absorbent bioplastics, which are those that can absorb between 10 and 1000 times their weight in water. After introducing different variants, the result obtained has been positive," said the University of Seville researcher Antonio Guerrero, head of the study.

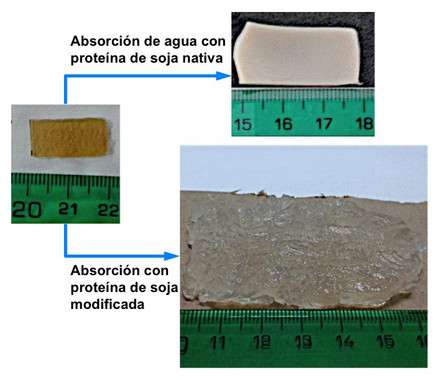

During the tests, the experts showed that the absorption properties of soya were altered. "Without interfering with its composition, soy is capable of absorbing 12 times its own weight, but if we modify its molecular structure to increase its attraction to water, this capacity is multiplied by three so that it reaches 36 times its initial weight—that's an increase of 3600 percent over its real weight," specified Guerrero.

To carry out the experiments, they processed the soya to extract the protein. With the aim of separating the liquid from the solid compounds, the scientists used the technique of freeze drying. "This method is gentler and less aggressive than atomization, so it has practically no effect on the protein. In this way, we managed to isolate the raw material with which we are going to work," Guerrero says.

After this process of dehydration, the experts mixed the now-modified isolated compound of the protein with a plasticiser. "We obtained a solid concentrate of proteins and, once this composition was prepared, we introduced it into an injection moulding machine and deposited it in a mold. From there, we obtained the test tube with which we are going to do the tests," explained the researcher.

Organic nutrient distributor

As well as having a higher absorption capacity than other conventional bioplastics, the researchers determined that this compound potentially has applications in horticulture, specifically as a distribution device for agricultural nutrients.

In fact, the next phase of this project is to study the viability of releasing these compounds in the country using natural dispensers formed from super-absorbent soya. To do this, they will simulate a piece of land in the laboratory and will place the moulds loaded with micronutrients like mineral salts, iron and zinc, to which they will keep adding water.

In this way, they will be able to test if, after the drainage phase and because of the action of these dispensers, the water contains nutrients and, if so, in what quantity. "We want to assure ourselves that what is produced is controlled and suitable for the needs of the soil. Also, as it is a biodegradable plastic made from soya proteins, the actual containers, once empty, will serve as substratum for the soil," Guerrero suggested.

Following this line of study, the researchers will continue experimenting with other products like rape and cotton, from which superabsorbent materials could be obtained with sanitary and agricultural industrial applications.

More information: A.A. Cuadri et al. Natural superabsorbent plastic materials based on a functionalized soy protein, Polymer Testing (2016). DOI: 10.1016/j.polymertesting.2016.12.024

Provided by University of Seville