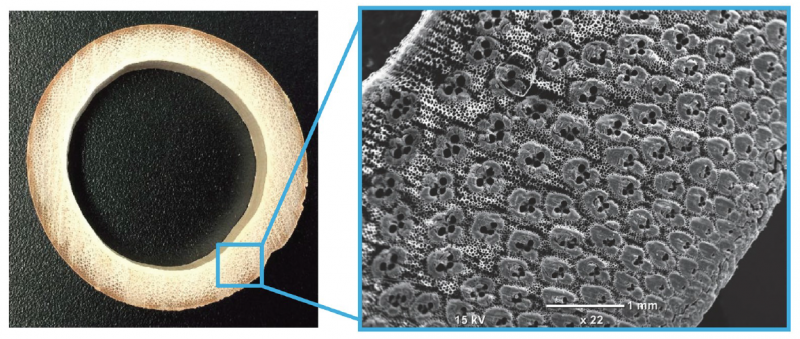

The cross section of a wild moso bamboo Phyllostachys pubescens. Fibers (vascular bundles) surrounding the heart-shaped black openings have a denser distribution toward the outer part. Credit: Sato M., et al., PLOS ONE, May 3, 2017

The spatial distribution of fibers in hollow bamboo cylinders is optimized to reinforce flexural rigidity, a new finding that sheds light on biomimetic approaches in the development of materials.

Light and tough, bamboo is widely used as a natural, functional material in Japan and other Asian countries. Bamboo is light because of its hollow structure, which allows the plant to grow faster with small amounts of woody parts and expose itself to sunlight above other trees. But this lightness also leaves bamboo vulnerable to strong crosswinds and can make it difficult for the plant to support its own weight. To overcome this shortcoming, the woody parts of bamboo are reinforced with thin but robust fibers (vascular bundles). Each fiber is as rigid as steel.

Examining a cross section of bamboo reveals that fibers in the woody parts are not equally distributed. The density of the fibers becomes gradually thicker from the inner to the outer surface, suggesting the outer parts are, mechanically speaking, stronger than the inner parts. This is reasonable because the outer parts receive more force when the cylinder is bent.

To determine the relationship between the distribution of the reinforcing fibers in a culm and the culm's flexural rigidity, researchers from Hokkaido University, Prefectural University of Kumamoto and the University of Yamanashi compared the data from the real bamboo's fiber distribution to the theoretically derived optimal fiber distribution.

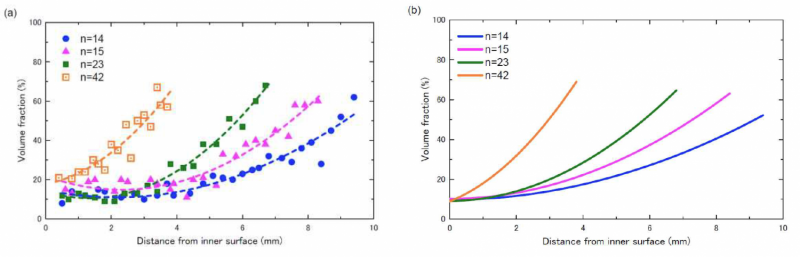

Surprisingly, the real bamboo data displayed almost the same fiber distribution as the one with the theoretical, optimal fiber distribution. Near the root of the culm, where a large number of fibers are found, the real fiber distribution matched the theoretically derived quadratic form for gradient distribution. Near the tip of the culm, where there are much fewer fibers than near the root, the experimental data matched the linear distribution calculated in accordance with the theory.

The gradient distribution curves in the real bamboo cross section (left) matched the curves calculated based on a mechanics theory for optimal flexural rigidity (right). The value of n is an internode number assigned from the root to the tip. Credit: Sato M., et al., PLOS ONE, May 3, 2017

As a result, the researchers found bamboo precisely adjusts the distribution of fibers so flexural rigidity is maximized with the smallest volume of wood material possible. The mechanical theory employed in this research, therefore, can be applied to other hollow cylinders to determine the gradient distribution that can optimize flexural rigidity.

"Our study could help develop advanced materials by mimicking the bamboo model for its lightness and toughness. Imitating the systems of animals and plants which have survived harsh conditions, an approach called biomimetics has proved successful in solving many problems in the development of materials in recent years," commented Motohiro Sato, the lead author at Hokkaido University.

More information: Motohiro Sato et al. Bamboo-inspired optimal design for functionally graded hollow cylinders, PLOS ONE (2017). DOI: 10.1371/journal.pone.0175029

Journal information: PLoS ONE

Provided by Hokkaido University