Contracts signed for ELT mirrors and sensors

Contracts for the casting of the M2 and M3 mirrors, their cells and sensors for the M1 segments were awarded at a ceremony at ESO's Garching Headquarters in January 2017. Credit: ESO

At a ceremony today at ESO's Headquarters four contracts were signed for major components of the Extremely Large Telescope (ELT) that ESO is building. These were for: the casting of the telescope's giant secondary and tertiary mirrors, awarded to SCHOTT; the supply of mirror cells to support these two mirrors, awarded to the SENER Group; and the supply of the edge sensors that form a vital part of the ELT's huge segmented primary mirror control system, awarded to the FAMES consortium.

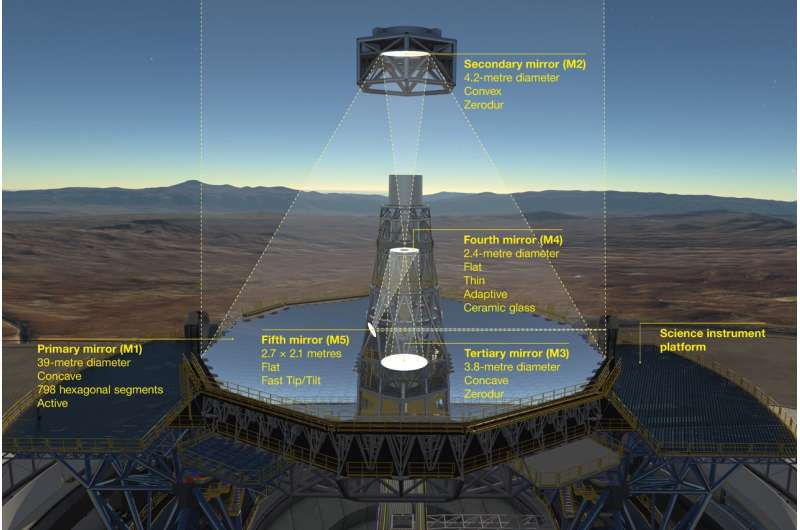

The construction of the 39-metre ELT, the largest optical/near-infrared telescope in the world, is moving forward. The giant telescope employs a complex five-mirror optical system that has never been used before and requires optical and mechanical elements that stretch modern technology to its limits.

Contracts for the manufacture of several of these challenging telescope components have just been signed by ESO's Director General, Tim de Zeeuw, and representatives of three industrial contractors in the ESO Member States.

Introducing the ceremony, Tim de Zeeuw said: "It gives me great pleasure to sign these four contracts today, each for advanced components at the heart of the ELT's revolutionary optical system. They underline how the construction of this giant telescope is moving ahead at full speed—on target for first light in 2024. We at ESO look forward to working with SCHOTT, SENER and FAMES—three leading industrial partners from our Member States."

The first two contracts were signed with SCHOTT by Christoph Fark, Executive Vice President. They cover the casting of the ELT's largest single mirrors—the 4.2-metre secondary and 3.8-metre tertiary mirror—from SCHOTT's low-expansion ceramic material Zerodur.

Hanging upside-down at the top of the telescope structure, high above the 39-metre primary mirror, the secondary mirror will be largest ever employed on a telescope and the largest convex mirror ever produced. The concave tertiary mirror is also an unusual feature of the telescope. The ELT secondary and tertiary mirrors will rival in size the primary mirrors of many modern-day research telescopes and weigh 3.5 and 3.2 tonnes respectively. The secondary mirror is to be delivered by the end of 2018 and the tertiary by July 2019.

The third contract was signed with the SENER Group by Diego Rodríguez, Space Department Director. It covers the provision of the sophisticated support cells for the ELT secondary and tertiary mirrors and the associated complex active optics systems that will ensure these massive, but flexible, mirrors retain their correct shapes and are correctly positioned within the telescope. Great precision is needed if the telescope is to deliver optimum image quality.

The fourth contract was signed by Didier Rozière, Managing Director (FAMES, Fogale), and Martin Sellen, Managing Director (FAMES, Micro-Epsilon), on behalf of the FAMES consortium, which is composed of Fogale and Micro-Epsilon. The contract covers the fabrication of a total of 4608 edge sensors for the 798 hexagonal segments of the ELT's primary mirror [6].

These sensors are the most accurate ever used in a telescope and can measure relative positions to an accuracy of a few nanometres. They form a fundamental part of the very complex system that will continuously sense the locations of the ELT primary mirror segments relative to their neighbours and allow the segments to work together to form a perfect imaging system. It is a huge challenge not only to make sensors with the required precision, but also to produce them quickly enough for thousands to be delivered to the necessarily short timescales.

The signing ceremony was also attended by other senior representatives of the companies involved and ESO. It was an excellent opportunity for representatives of the contractors producing many of the giant telescope's optical and mechanical components to get to know each other informally as they begin to help create the world's biggest eye on the sky.

Provided by ESO