Method to genetically engineer bacteria and yeast to increase bioethanol production

Scientists from Illinois Institute of Technology received a patent for a method to genetically engineer bacteria and yeast to increase bioethanol production, especially from cellulosic material in biomass like twigs, branches, plant stalks and husks, and woodchips.

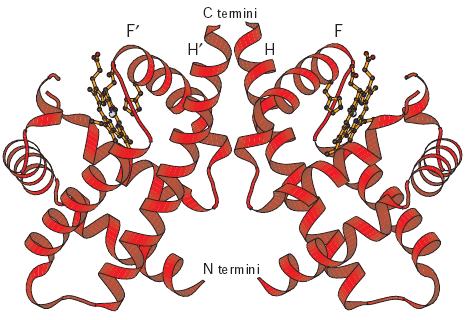

Ben Stark, professor of biology, and former Ph.D. student Tony Sanny, now a partner with Swanson & Bratschun, developed a method to genetically engineer Escherichia coli and Zymomonas mobilis, two bacterial ethanol producers, and yeast, a eukaryotic ethanol producer, to express Vitreoscilla hemoglobin (VHb). Engineering of microorganisms with VHb has been shown to enhance the production of many useful bioproducts as well as improve microbial degradation of certain toxic chemicals. Physical addition of small amounts of oxygen to ethanol producing cultures has been shown by others to enhance bioethanol production; the Illinois Tech (VHb) approach is a biological correlate of the physical method, and so works on its own without the need for an oxygen feed to the growth chamber.

Bioethanol is a liquid fuel that comprises about 10 percent of the gasoline at the pump. It is made by microorganisms by fermentation of sugars. The sugars come from various sources, including starch from plants like corn; sugar from sugar cane and sugar beets; or cellulose and hemicellulose, polymers of various sugars that are among the main structural components in wood and plants in general that give them their strength.

Cellulosic and hemicellulosic-based bioethanols are the least common right now, because these polymers are fairly difficult to break down into their component sugars, and this factor makes it difficult to produce enough fuel-grade ethanol cost-effectively. On the other hand, bioethanol from these feedstocks has the promise of being much more cost effective and sustainable, producing less greenhouse gas, and having a less direct impact on the food supply than using corn starch as a source of sugar. Work in recent years has focused on genetically modifying yeast and other materials used in producing bioethanol from cellulose and hemicellulose to speed the breakdown process, improve yields, and lower costs.

This patent is Stark's and Sanny's third since 2014 for increasing bioethanol production by genetic engineering of microorganisms to express Vitreoscilla hemoglobin.

Provided by Illinois Institute of Technology