Chinese researchers develop new battery technology

A Chinese research team has developed a novel, environmentally friendly, low-cost battery that overcomes many of the problems of lithium ion batteries (LIB). The new aluminum-graphite, dual-ion battery (AGDIB) offers significantly reduced weight, volume, and fabrication cost, as well as higher energy density in comparison with conventional LIBs. AGDIB's electrode materials are composed of environmentally friendly, low cost aluminum and graphite, while its electrolyte is composed of conventional lithium salt and carbonate solvent.

The research, published in "A Novel Aluminum-Graphite Dual-Ion Battery," recently appeared in Advanced Energy Materials.

The discovery is particularly important given rising battery demand and existing LIB technology, which is reaching its limit in specific energy (by weight) and energy density (by volume).

LIBs are widely used in portable electronic devices, electric vehicles and renewable energy systems. Battery disposal creates major environmental problems, since most batteries contain toxic metals in their electrodes. According to the Freedonia Group, world battery demand is expected to rise 7.7 percent annually, reaching U.S. $120 billion in 2019.

"Compared with conventional LIBs, this battery (AGDIB) shows an obvious advantage in production cost (~ 50 percent lower), specific density (~1.3-2.0 times), and energy density (~1.6-2.8 times)," said TANG Yongbing, leader of the research team. The AGDIB mechanism follows a dual ion intercalation/alloying process.

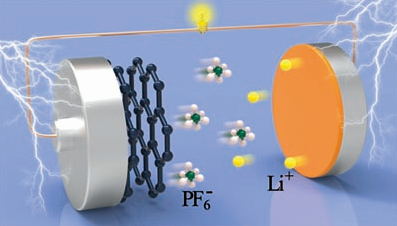

Upon charging, anions in the electrolyte intercalate into the graphite cathode, while the Li+ ions in the electrolyte deposit onto the aluminum counter electrode to form an Al-Li alloy. The discharge process is the reverse of the charging process, where both anions and Li+ ions diffuse back into the electrolyte. Since the Al counter electrode in the AGDIB acts as the anode and the current collector at the same time, the dead load and dead volume of the AGDIB is significantly reduced, making a battery with both high specific energy density and high volume energy density.

In its research, the team roughly estimated the specific energy density and power density of the AGDIB according to the configuration of the packaged battery. Results show that the AGDIB can deliver a specific energy density of ~222 Wh kg-1 at a power density of 132 W kg-1, and ~150 Wh kg-1 at 1200 W kg-1. Compared with commercial LIB (~200 Wh kg-1 at 50 W kg-1, and ~100 Wh kg-1 at 1000 W kg-1) and electrochemical capacitors (~5 Wh kg-1 at 5000 W kg-1), the AGDIB showed significantly improved performance.

Importantly, the volume energy density of the AGDIB can reach ~560Wh/L which is much higher than traditional batteries (~350 Wh/L for Tesla Model S and ~200 Wh/L for BYD E6). For example, a 500 kg, AGDIB-based power battery could reach a recharge mileage of ~550 km (~425 km for Tesla Model S and ~225 km for BYD E6), and a 200 L AGDIB-based power battery could reach a mileage of about 560 km.

This AGDIB shows real potential for large-scale application in both electronic devices and electric vehicles. This technology may represent a revolutionary step for China's energy industry. The successful commercialization of this new type battery has great potential to significantly enhance the performance of portable electronic devices, electric vehicles, and renewable energy systems, etc.

More information: Xiaolong Zhang et al. A Novel Aluminum-Graphite Dual-Ion Battery, Advanced Energy Materials (2016). DOI: 10.1002/aenm.201502588

Journal information: Advanced Energy Materials

Provided by Chinese Academy of Sciences