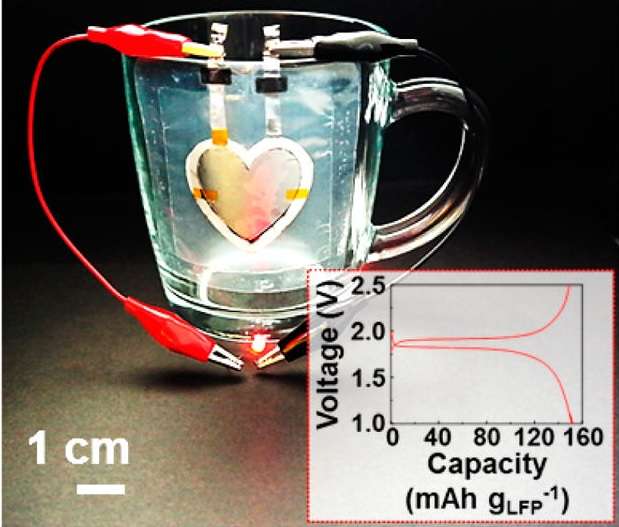

A Li-ion heart-shaped battery printed on a glass cup is used to light an LED. Credit: Kim, et al. ©2015 American Chemical Society

Scientists have developed a new technique that can print batteries on almost any surface, which is expected to be essential for future flexible electronics such as roll-up displays, smart electronic clothing, and Google Glass-type devices. Whereas today's Li-ion batteries can be fabricated only in fixed shapes and sizes, such as cylinders or pouch cells, the new Li-ion batteries can be printed in their entirety—including electrodes and electrolyte—almost anywhere. The researchers even predict that in the future the batteries could be printed with a 3D printer into various 3D shapes.

The researchers, led by Sang-Young Lee, Professor at the Ulsan National Institute of Science and Technology (UNIST) in South Korea, have published a paper on the new printable solid-state (PRISS) Li-ion batteries in a recent issue of Nano Letters.

In conventional Li-ion battery manufacturing, the electrodes and separator membranes are stacked or wound around each other and packaged into metallic cases, which are then injected with liquid electrolytes. It's been difficult to fabricate batteries in diverse shapes and sizes due to the fact that the liquid electrolytes are combustible and may leak if not packaged well, and also because the separator membranes are necessary for preventing contact between the electrodes.

The new battery manufacturing method does not require either liquid-electrolyte injection or separator membranes. Instead, the electrolyte is made of a paste, the electrodes are made of a slurry, and they are consecutively printed onto a surface and then cured with ultraviolet light. Because the electrolyte paste is printed in between the electrodes, it also plays the role of the separator membrane. The slurry and paste can also be printed through a stencil, allowing for batteries to be printed in different shapes, letters, and designs.

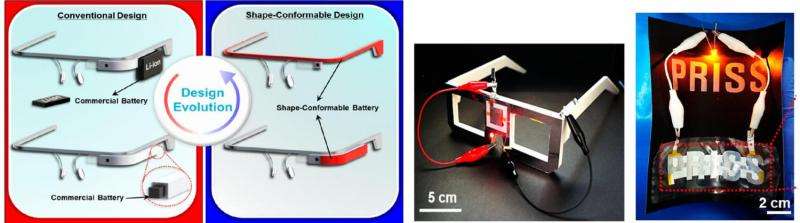

Printable battery examples include seamless integration into eyeglass lenses, as well as batteries printed on paper eyeglasses and in the form of the letters “PRISS” on a flexible material. Credit: Kim, et al. ©2015 American Chemical Society

"All battery components, such as cathodes, anodes and electrolytes, can be printed on arbitrary objects of complex geometries, thereby enabling the seamless integration of shape-conformable solid-state rechargeable batteries with various form factors into complex-shaped (such as curvilinear) objects," Lee told Phys.org. "We envision that the printable battery presented herein holds a great deal of promise for potential use in forthcoming wearable electronics and IOTs (Internet of Things), which eventually removes pre-designated battery space with fixed dimension and shape."

For a couple examples, the scientists printed a heart-shaped battery on a cup, printed another battery on paper eyeglasses resembling Google Glass, and also printed the letters "PRISS" on paper. Because the printed batteries are so seamlessly integrated into the surface of these objects, in a way it appears that there is no battery there at all. However, connecting cables to these battery-embedded surfaces shows that they can power LEDs.

Overall, the printed battery performance is competitive with that of other flexible batteries, demonstrating good long-term storage capacity, 90% capacity retention after 30 cycles, and no detectable change in electrical resistance during repeated bending cycles. Still, in the future the researchers plan to improve certain areas, including increasing the energy density and prolonging the battery life.

Another area of future research is combining the PRISS batteries with high-precision inkjet printing and 3D printing, which will lead to even more unprecedented design opportunities.

"To extend application fields of the printable batteries, we are currently considering a wide variety of printing techniques," Lee said. "Ink-jet and 3D printing can be recommended as a promising technology to enable the facile fabrication of multidimensional/multiscale complex-structured power sources. An urgent prerequisite to achieve this goal is that printable battery components should be precisely tuned to fulfill the rheological requirements of each printing technology, without impairing electrochemical properties. Our group has recently achieved some intriguing results on printable batteries with ink-jet and 3D printing technology, which will provide completely new application fields of rechargeable power sources that we have not yet encountered."

More information: Se-Hee Kim, et al. "Printable Solid-State Lithium-Ion Batteries: A New Route toward Shape-Conformable Power Sources with Aesthetic Versatility for Flexible Electronics." Nano Letters. DOI: 10.1021/acs.nanolett.5b01394

Journal information: Nano Letters

© 2015 Phys.org