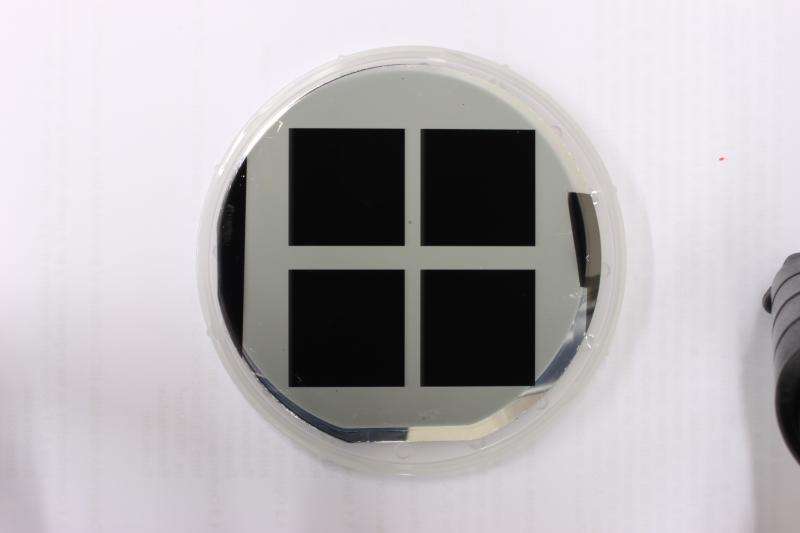

Solar cell with a black silicon surface treatment

Researchers at the Department of Electronic Engineering of the Universitat Politècnica de Catalunya (UPC) have obtained a record efficiency of 22% with silicon solar cells that incorporate a surface treatment called black silicon on the front of the cell. This technique coats the surface with a dry chemical that results in small conical tips at the nanometric scale.

Incorporating black silicon reduces the loss of energy caused by the reflectance of solar cells to almost zero. This significantly increases the yield, by almost 4% compared with traditional solar cells. In fact, it is called black silicon because, at first glance, the treated surface is black (and does not reflect light), whereas standard cells are blue. This extra improvement in efficiency would allow a refrigerator, for example, to run for a day in a photovoltaic system composed of a 5 m2 panel.

Solar cells are the main element of solar panels, which are installed to capture sunlight and convert it to electricity. Generally, to ensure that they reflect as little light as possible and thus prevent energy loss, solar cells are textured using an alkaline bath that forms a rough surface on which pyramids are randomly distributed. This technique makes the cells thicker because it consumes a significant amount of silicon in the process. Black silicon, however, allows very thin silicon cells to be used, lowering production costs and saving silicon.

An added advantage achieved by researchers from the UPC and Aalto University in Finland is that, given the ability of black cells to capture solar radiation from lower angles, more electricity can be generated during a longer period throughout the day compared with traditional cells. In Finland, this feature is very important, because the sun shines from a low angle for most of the year and it has been demonstrated that cells made with black silicon generate more electricity than traditional cells that have the same degree of efficiency.

According to the UPC researcher Pablo Ortega, "within about three to four years it will be feasible to apply black silicon in the solar panel industry and the market in general."

An oxidation oven used in the process of manufacturing black silicon cells

More information: "Black silicon solar cells with interdigitated back-contacts achieve 22.1% efficiency." Nature Nanotechnology (2015) DOI: 10.1038/nnano.2015.89

Journal information: Nature Nanotechnology

Provided by Universitat Politècnica de Catalunya