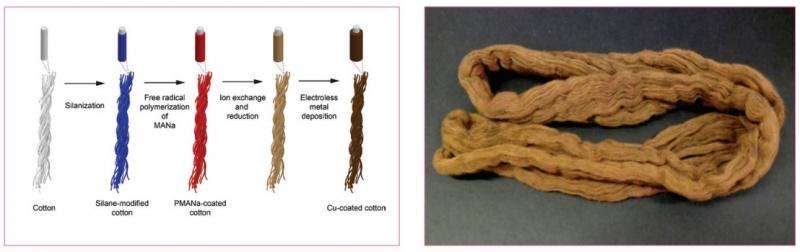

(Left) Schematic illustration of the process of preparing conductive cotton yarns via in-situ free radical polymerization (Only grafting of PMANa is illustrated here. Grafting of PAANa follows the same procedures). (Right) As-made PMANa-assisted copper-coated cotton yarns. Credit: Hong Kong PolyU

In a new method for preparing electrically conductive textiles, the textile surface is modified with a negatively charged polyelectrolyte poly(methacrylic acid sodium salt) (PMANa) or poly(acrylic acid sodium salt) (PAANa) by in-situ free radical polymerization, and then treated with electroless metal deposition.

The as-fabricated conductive textiles preserve robust mechanical and electrical stability under repeated cycles of rubbing, stretching and washing. They can be integrated into wearable electronics to replace the conventional rigid conductive electrodes and wires.

Special Features and Advantages:

- The negatively charged polymer interfacial layer that bridged the deposited metal and the textile surface provides the metal layer with outstanding adhesion properties and good washing durability.

- The method is low cost (without expensive catalyst) and readily applicable to the industry to develop scale production of high performance conductive textiles.

Applications:

- Flexible electronic interconnects, contacts and electrodes, especially for wearable electronics, smart textile and fashion

- EMI shielding, electrostatic discharge, thermal control materials

Provided by Hong Kong Polytechnic University