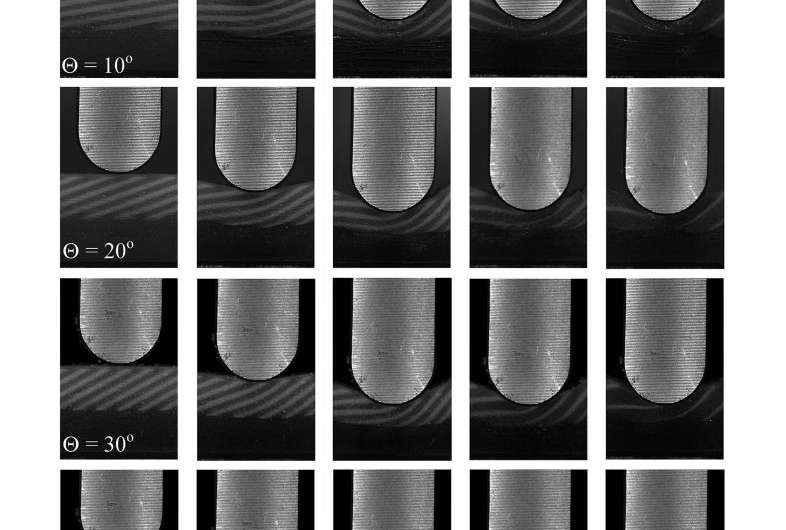

Illustration of deformation mechanisms in laminates. Credit: Soft Matter, 2015,11, 2547-2554. DOI: 10.1039/C4SM02907K

Body armor. Through the ages creative thinking problem-solving have gone into thinking up solutions to protect those in combat. This is where materials science, computer science, engineering and chemistry intersect as modern scientists play their part in developing protective armor. Popular Science contributor Kelsey Atherton wrote about one recent step forward, with MIT researchers turning to armor inspired by fish scales.

Man is hardly alone in developing effective dermal armor. Fish, after all, are flexible yet also are protected by hard scales. Specifically, researchers are inspired by the imbricated scale-tissue flexible armor of elasmoid fish. A team set out to design hybrid stiff plate/soft matrix material architectures. They wanted to show their ability to provide protection against penetration while preserving flexibility. The researchers, led by mechanical engineer Stephan Rudykh, have designed a flexible armor where strength and flexibility are not tradeoffs but go hand in hand. Generally, strength and flexibility are competing properties, said Technion Assistant Professor Stephan Rudykh.

"The secret behind this material is in the combination and design of hard scales above with soft, flexible tissue below," he stated, in a report by Kevin Hattori last month. Rudykh heads the Technion's Mechanics of Soft Materials Laboratory.

Earlier this year, Rudykh and other authors' work, "Flexibility and protection by design: imbricated hybrid microstructures of bio-inspired armor," was published in Soft Matter. The article highlighted the work. It outlined the characteristics, test results and applications of the new material. The authors wrote, "we perform indentation tests for estimating protective properties resisting penetration events and three-point bending for estimating the flexibility of 3D-printed composites over a range of microstructural parameters."

The three authors of the paper are Rudykh, Christine Ortiz, and Mary Boyce. Institutions represented are MIT, Columbia, and Technion-Israel Institute of Technology. As the paper stated, "Indentation and bending tests on bio-inspired 3D-printed prototype materials show that both protection and flexibility are highly tunable by geometrical parameters of the microstructure (plate inclination angle and volume fraction). We show that penetration resistance can be amplified by a factor of 40, while flexibility decreases in less than 5 times."

In their summary, they said, "We introduced a new metric for material performance that incorporates the conflicting performance requirements of penetration resistance and flexibility in one parameter, namely protecto-flexibility," they stated. According to Hattori's report, "If the application is, for example, a military uniform for combat, more flexibility can be built into the areas needing flexibility, such as the elbows and knees, while the anti-penetration properties elsewhere, such as in the upper body, can be beefed-up."

Essentially, the scientists are offering new guidelines for developing material architectures that retain flexibility while offering protection with highly tunable properties. Fabric can be tailored to the wearer's body and the environment that the wearer will face. Prof. Rudych said, "This work is part of a revolution in materials properties. Once we can gain control over a material's micro properties, using 3-D printing we can create materials of an entirely different type, each with the ability to be adjusted to fit the wearer, the need, and the environment."

Atherton wrote, "In the future soldiers could have fish-scale suits of armor that are more flexible around joints and sturdier across the rest of the body, adding greater protection where none was before without diminishing any of the value of previous armor."

This armor is still in the early testing stages. Next stages include trying the armor against bullets and shrapnel. Hattori said the team is moving into tests using fast-moving projectiles, both bullets and small particles, while also testing the flexibility attribute under pressure.

More information: Flexibility and protection by design: imbricated hybrid microstructures of bio-inspired armor, Soft Matter, 2015,11, 2547-2554. DOI: 10.1039/C4SM02907K (PDF)

Abstract

Inspired by the imbricated scale-tissue flexible armor of elasmoid fish, we design hybrid stiff plate/soft matrix material architectures and reveal their ability to provide protection against penetration while preserving flexibility. Indentation and bending tests on bio-inspired 3D-printed prototype materials show that both protection and flexibility are highly tunable by geometrical parameters of the microstructure (plate inclination angle and volume fraction). We show that penetration resistance can be amplified by a factor of 40, while flexibility decreases in less than 5 times. Different deformation resistance mechanisms are found to govern flexibility (inter-plate matrix shear) versus penetration resistance (localized plate bending) for this microstructural architecture which, in turn, enables separation of these functional requirements in the material design. These experiments identify the tradeoffs between these typically conflicting properties as well as the ability to design the most protective material architecture for a required flexibility, providing new design guidelines for enhanced flexible armor systems.

Journal information: Soft Matter

© 2015 Tech Xplore