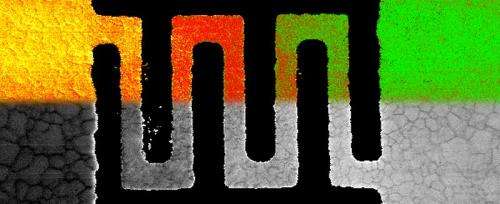

This composite image shows density (grey) and temperature (color) maps of a 100 nm-wide polycrystalline aluminum wire. The temperature is computed from the density using aluminum's known thermal expansion. Lower densities appear at crystal-grain boundaries, which are atomic-scale features, and where thermal expansion has caused the aluminum to expand. One end of the wire (green) is near room temperature, and the other (orange) is 160 K warmer. Credit: USC CEMMA & UCLA Regan Group

A team of researchers with the University of California has found a way to use a transmission electron microscope (TEM) as a thermometer for measuring heat in micro-electric devices. In their paper published in the journal Science, the team describes how they discovered using a TEM on a tiny piece of metal could reveal its density change as electrons passed through. Christian Colliex with the L'Université de Paris, offers a Perspective piece on the work by the team in the same journal edition.

As microelectronics have grown smaller, it has become more difficult to take their temperature, a necessary part of transistor design—traditional methods such as contact thermometers or radiative measurements become les viable as they tend to add heat or offer poor resolution. That means that scientists have had to look for other ways to get the job done. In this new effort, the researchers went back to one of the original designs, the old-school mercury thermometer, for inspiration. Such old time thermometers were able to note temperature differences because the density of the mercury changed predictably as the temperature changed. The density of other metals change due to temperature differences as well, and that was the approach the team used to measure temperature changes in a very small metal wire.

When electricity is sent through a wire, it causes a density change in the wire due to charge vibrations, which can be seen using a TEM at nanometer scale. The researchers sent electricity through a tiny aluminum wire while simultaneously scanning it with a TEM—as the electrons passed through the wire, energy was transferred to the wire in the form of charge oscillations causing a density change—the amount varied by the type of metal used, the team noted. To calculate the temperature of the wire, the researchers simply compared its density with an identical wire sitting at room temperature. The team has dubbed their technique plasmon energy expansion thermometry (PEET).

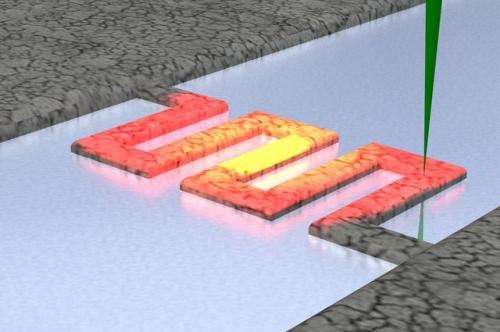

Artist’s conception of plasmon energy expansion thermometry showing a focused electron beam penetrating a 100 nanometer wide aluminum wire atop a thin glass window. The wire’s temperature is mapped by scanning the electron beam. Credit: CEMMA and Regan Group

The team claims that their technique could very easily be used in measuring temperatures in actual microelectronic devices and that it could be done using general electron microscopy as well. All it would take, they suggest is the introduction of tiny aluminum nanoparticle samples just next to those metals they are trying to measure.

More information: Science 6 February 2015: Vol. 347 no. 6222 pp. 629-632. DOI: 10.1126/science.aaa2433

Journal information: Science

© 2015 Phys.org