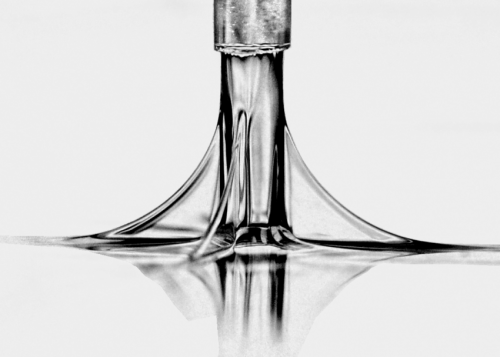

Spreading wings. A jet of viscoelastic fluid (polyethylene glycol) forms wings when it impacts a glass plate. The fluid flows more slowly through the wings, which generates a polygon, rather than a circle for the flat sheet of fluid around the impact point. The edges of the polygon are defined by a flow disturbance called a hydraulic jump. Credit: H. Lhuissier/Paris Diderot Univ/Physics Focus

(Phys.org) —A trio of researches with Université Paris Diderot has found that viscoelastic fluids spontaneously form wings which in turn cause the formation of geometric shapes when the fluid is shot out of a jet at high speed. In their paper published in the journal Physical Review Letters, Henri Lhuissier, Baptiste Néel and Laurent Limat describe the attributes of the fluids as they were tested and observed in their lab.

The researchers note that when ordinary liquids, such as water, are shot out of jet down onto a flat surface at close range, the fluid will form a circle on the surface as it spreads out. In this new effort, the researchers found that the same cannot be said for viscoelastic fluids (those that are "thick" such as pastes, gels, honey, etc.) Their findings were part of research looking into the possibility of causing such liquids to atomize the way ordinary liquids do, a necessity for using them in engines.

The researchers found that when viscoelastic fluids were shot downward onto a flat surface at close range (less than one centimeter) at high speed (a least one meter per second), the fluid tended to form "wings" in the space between the nozzle and the flat surface. As the fluid struck the surface, each of the wings flowed outward forming a single geometric shape, with corresponding edges. Taken together the shapes formed pentagons on the flat surface, or other shapes with more or fewer edges and sizes, depending on changes to velocity and distance.

The researchers speculate that this previously unknown characteristic of such liquids is due primarily to friction between the liquid that touches the inside of the jet and the material that makes up the inside of the jet. A closer look showed that the fluid was moving faster in the center of the jet stream than it was on the outside edges, indicating something had caused a difference in flow speed. Viscoelastic fluids have longer-chain molecules (polymers) compared to ordinary fluids, which accounts for their apparent "thickness." As they are shot out of a jet, the friction against the insides of the nozzle causes the polymers to stretch. The result, the researchers surmise is a competition that erupts between elastic stress and surface tension.

The researchers don't know if their findings will have any practical value, but suspect that what they've observed might apply to liquid drop formation, flow focusing and other viscoelastic fluid research applications.

More information: Viscoelasticity Breaks the Symmetry of Impacting Jets, Phys. Rev. Lett. 113, 194502 – Published 7 November 2014. dx.doi.org/10.1103/PhysRevLett.113.194502

ABSTRACT

A jet of a Newtonian liquid impacting on a wall at right angle spreads as a thin liquid sheet which preserves the radial symmetry of the jet. We report that for a viscoelastic jet (solution of polyethylene glycol in water) this symmetry can break; close to the wall, the jet cross section becomes faceted and radial steady liquid films (wings) form, which connect the cross-section vertices to the sheet. The number of wings increases with increasing the viscoelastic relaxation time of the solution, but also with increasing jet velocity and decreasing distance from the jet nozzle to the wall. We propose a mechanism for this surprising destabilization of the jet shape, which develops perpendicularly to the direction expected for a buckling mechanism, and explain these dependencies. We also discuss the large-scale consequences of the jet destabilization on the sheet spreading and fragmentation, which show through the faceting of hydraulic jumps and of suspended (Savart) sheets.

Journal information: Physical Review Letters

© 2014 Phys.org