Scientists demonstrated that when using in situ liquid transmission electron microscopy and scanning TEM to probe nanomaterials that the choice of electron beam energy has a strong influence that goes far beyond merely increasing the concentration of reducing radicals.

Accurately examining materials in liquids using electron microscopy is a difficult task for scientists, as electron beams perturb the sample and induce artifacts. This is especially true when using in situ liquid transmission electron microscopy (TEM) and scanning TEM (STEM) to probe nanomaterials. Scientists at Pacific Northwest National Laboratory (PNNL) and University of California, Davis demonstrated that in in situ liquid experiments, the choice of electron beam energy has a strong effect that goes far beyond merely increasing the concentration of reducing radicals. They also found that when compared to solid samples, radicals formed in the liquid phase are more mobile, and ultimately dictate the choice of TEM imaging mode.

The PNNL team established procedures to understand the effect of an electron beam on a liquid sample, highlighted the rationale behind choosing the optimal experimental conditions for quantification, and identified the experimental factors that require further scrutiny to achieve fully quantitative results in liquid STEM experiments.

"The ultimate limitation to spatial resolution in the fluid stage is the local structural damage to the sample caused by the electron beam," said Dr. Patricia Abellan, a postdoctoral fellow at PNNL. "The sample-beam interaction therefore not only determines the reproducibility and accuracy of in situ fluid cell STEM data, but also dictates the attainable spatial resolution."

Imaging techniques use environmental fluid stages in an increasing range of applications, including electrochemical deposition of copper and lead; nanostructure growth; observation of macromolecular complexes, soft materials, and biological cells; and the lithiation and delithiation of silicon nanowire electrodes during battery cycling, to name a few.

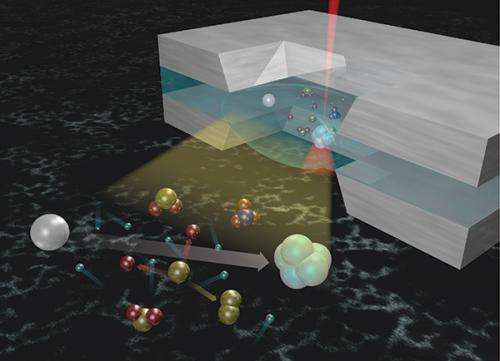

In the fluid stage, sealed windowed cells are used, where a liquid layer is trapped between two thin, amorphous silicon nitride membranes supported by rigid silicon chips. An opening etched in the center of each chip defines an electron transparent region where the liquid is imaged. As the technique is increasingly refined, the challenge becomes obtaining quantifiable and reproducible data that is free from beam-induced artifacts.

"Our beam energy-dependent results reveal that the damaging effect of electrons in liquid samples cannot be simply explained by considering the electron flux and the concentration of reducing radicals created," said Abellan. "The experiments at 80 kV suggest that the relative amount of oxidizing to reducing radicals increases at lower beam energies, which leads to a significant back reaction that may inhibit nanocrystal growth."

Using liquid phase TEM and STEM images recorded using systematically varied experimental parameters, the team analyzed the effects of the different conditions used-including imaging modes and beam currents that control how varying amounts of electron doses are delivered to the sample-on the experimental observables.

They provided an overview of the beam-sample interactions important to quantification that have been identified for a range of experimental conditions used for imaging. They visualized the effect of changing beam energy, changing imaging mode, of precursor solution depletion, and cumulative charge through the growth of silver nanoparticles from an aqueous silver precursor that was previously calibrated for the effect of electron dose.

The team will study the effect of thickness on quantification, and apply the described techniques and protocols in a number of biological and materials sciences problems.

More information: Abellan P, TJ Woehl, LR Parent, ND Browning, JE Evans, and I Arslan. 2014. "Factors Influencing Quantitative Liquid (Scanning) Transmission Electron Microscopy." 2014. Chemical Communications 50(8):4873-4880. DOI: 10.1039/c3cc48479c

Journal information: Chemical Communications

Provided by Pacific Northwest National Laboratory