Biological material derived from plants represents a promising source for renewable and sustainable biofuel production, but there is a lack of cost-effective and efficient enzymes for converting plant-derived carbohydrates to biofuels. This study systematically evaluates the specific physical and chemical properties of biomass that hinder the performance of commercial enzyme products.

By identifying specific deficiencies in currently available enzymes, this research reveals targeted strategies for improving the efficacy of enzymes to convert biomass to biofuels. This information can be used to design, screen and discover highly efficient plant cell-wall degrading enzymes that will significantly help to reduce the formidable economic burden associated with the biochemical-based biomass-to-biofuel production process.

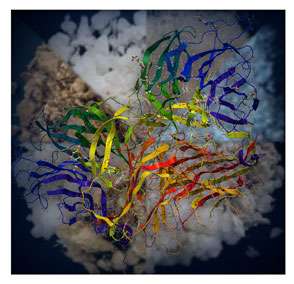

Biofuels are produced from plant-derived biomass through the breakdown of the plant cell wall, which contains sugars that can be used for energy. A considerable amount of effort has been directed to developing effective enzymes for degrading the cell wall, but the development of more efficient and cost-effective enzymes for biomass-to-biofuel conversion has been limited for several reasons. For one, it is not well understood how enzymes interact with biomass substrates, which have highly complex and heterogeneous physical and chemical properties. Moreover, there is a lack of adequate biomass model substrates for evaluating the efficacy of different enzymes.

To address this problem, researchers from Washington State University, in collaboration with scientists from EMSL, have developed a set of biomass reference substrates with controlled physical and chemical properties which can be used to identify specific deficiencies of cellulase enzymes in breaking down carbohydrate polymers. In a new study, the researchers used these reference substrates to test the effectiveness of three commercially available enzyme mixtures—Novozymes Cellic Ctec2, Dupont Accellerase 1500, and DSM Cytolase CL—using X-ray photoelectron spectroscopy, X-ray diffraction and an atomic force microscope at EMSL, the Environmental Molecular Sciences Laboratory, a DOE national scientific user facility.

They found that lignin hindrance and cellulose reactivity are still major recalcitrance factors that limit efficient hydrolysis of lignocellulose by these enzymes. Developing weak-lignin binding enzymes through genetic engineering and high-throughput screening can significantly improve the efficacy of commercial enzymes. A clear understanding of the mechanism of enzyme-catalyzed cellulose decrystallization is a critical step for identifying highly active enzymes for plant cellulose. Employment of the reference substrates as the sole carbon source during mutant screening could be a powerful tool for selecting higher and more specific cellulase hydrolytic activity toward realistic pretreated lignocellulosic substrates.

More information: Ju, X., Bowden, M., Engelhard, M., Zhang, X. "Investigating commercial cellulase performances toward specific biomass recalcitrance factors using reference substrates." Appl Microbiol Biotechnol. (2013). DOI: 10.1007/s00253-013-5450-4

Provided by Environmental Molecular Sciences Laboratory