Panasonic Corporation today announced that its 12V Energy Recovery Systems that use nickel metal hydride (Ni-MH) batteries are installed in the new idle-stop vehicles just rolled out by Nissan Motor Co., Ltd. and Mitsubishi Motors Corporation, the Nissan DAYZ ROOX and Mitsubishi eK Space. The new models were designed and developed for the Japanese market by NMKV Co., Ltd., a joint venture formed by the two automakers.

With growing environmental awareness, consumers are increasingly opting for eco cars such as hybrid electric vehicles (HEV) as well as vehicles employing idle-stop systems in pursuit of fuel economy. However, because conventional idle-stop systems depend on a single lead-acid battery to take care of all electrical needs of the vehicle, from restarting the engine to running the air-conditioner and other electrical components with the engine off, the battery is used very often.

Panasonic's 12V Energy Recovery System not only solves this problem but also improves fuel economy using recovered energy efficiently and extends the service life of the main lead-acid battery, thus contributing to increased performance of idle-stop vehicles. The system has the same 12V voltage as the main lead-acid battery and adopts Panasonic's Ni-MH battery cells that can endure high-temperatures. As a result, the system eliminates the need for voltage trasnformation and enables simplification of the control and cooling systems - which are highly praised by Nissan and Mitsubishi.

Panasonic is strengthening the development and business of lithium-ion and Ni-MH batteries for eco cars, and already has a successful record of supplying batteries for electric vehicles, plug-in hybrids and HEVs for multiple automobile manufacturers around the world. Panasonic's Ni-MH batteries are durable and able to maintain a high charging/discharging capacity over an extended period of time. This is supported by the company's unique battery manufacturing technologies, including polar plate sintering technology. Panasonic also has many years of experience in building battery systems, such as those incorporating batteries with a battery control that optimizes the performance of each battery.

Panasonic will continue to accelerate the development and commercialization of high performance batteries and battery systems to expand its eco car battery business on a global scale.

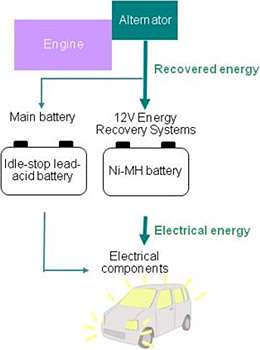

12V Energy Recovery System

- Battery: 10 x D size Ni-MH battery cells for automobiles

- Voltage: 12 V

- Capacity: 6Ah

- Size: 230 x 205 x 80mm

- Weight: Approximately 3.4kg

- [Major Features of 12V Energy Recovery System]

- The 12V energy recovery system improves fuel economy by supplying the recovered energy to the electrical components.

- The system has the 12V voltage that can be fitted to existing idle-stop systems without the use of a transformer. The system adopts Ni-MH battery cells that have outstanding high temperature performance.

- Contribution to increased service life of the main lead-acid battery.

Concept Diagram of 12V Energy Recovery System

Provided by Panasonic Corporation