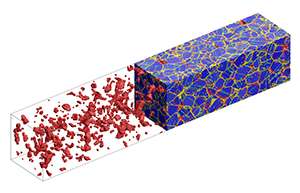

A simulation of nanocrystalline nickel under strain shows voids (red) appearing as the grains slide around. Credit: Elsevier

Experimentalists searching for strong structural materials have established that nanocrystalline metals, which have average grain sizes smaller than 100 nanometers, are stronger, harder and more resistant to fatigue than coarser-grained metals. Despite this strength, nanocrystalline metals undergo problematic deformations in response to loading or heating. To date, researchers have struggled to verify the complex interplay of processes that lead to these deformations.

Now, Zhaoxuan Wu and co-workers at the A*STAR Institute of High Performance Computing in Singapore and the University of Pennsylvania, United States, have used large-scale molecular dynamics simulations to demonstrate the main deformation mechanisms in nanocrystalline nickel nanowires. Until now, these mechanisms have been impossible to observe in the lab.

"Our study was inspired by the convergence of sample size in experiments and simulations," explains Wu. "Experimentalists are now working on materials at scales of tens of nanometers. At the same time, increases in computer speed allow us to simulate such materials at similar scales. This gives us an opportunity to study the deformation of nanocrystalline metals in full detail, with minimal assumptions."

Within their simulations, the researchers prepared a virtual sample of bulk nanocrystalline nickel with an average grain size of 12 nanometers, and 'cut out' nanowires with diameters of 8 to 57 nanometers. The researchers were then able to stretch and release the virtual nanowires at a constant temperature while tracking the positions of individual atoms. This provided some detail—at an unprecedented atomic scale—about the changes in the crystal configurations as the stretched nanowires underwent plastic deformation and eventually snapped.

In particular, the simulations of a stretched nanowire showed that the strains between neighboring atoms were large at crystal grain boundaries, but negligible within the grains or at the free surfaces. These strains led to sliding of grain boundaries, which quickly caused the total failure of thin nanowires with diameters similar to the grain size.

In thicker wires, where many of the grains were constrained by other surrounding grains, there was less boundary sliding at low strains. However, at higher strains the grain boundaries became aligned and voids appeared between the crystal grains, eventually leading to failure (see image).

"We think that the deformation anatomy that we observed could be representative of a broad set of nanocrystalline materials," says Wu. "We plan to simulate more nanocrystalline metals and alloys, including samples with impurities, which will be closer to laboratory conditions than our current study of pure nanocrystalline nickel."

More information: Wu, Z. X., Zhang, Y. W., Jhon, M. H. & Srolovitz, D. J. Anatomy of nanomaterial deformation: Grain boundary sliding, plasticity and cavitation in nanocrystalline Ni. Acta Materialia 61, 5807–5820 (2013). dx.doi.org/10.1016/j.actamat.2013.06.026