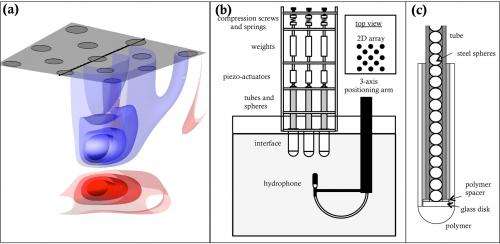

(a) Illustration of a sound bullet, where the surfaces are contours of constant pressure. The positive (red) and negative (blue) regions of the sound bullet are compact in 3D. (b) Experimental set-up of the acoustic lens, which is composed of 13 chains arranged in a square lattice. The hydrophone is used to measure sound under water. (c) Cross section of one of the chains and its casing. Credit: Donahue, et al. ©2014 AIP Publishing LLC

(Phys.org) —Scientists have developed an acoustic lens that produces pressure pulses that are so intense they're called "sound bullets." Although they are too high-pitched to be audible to the human ear, the sound bullets could have a variety of uses such as in medical ultrasound, underwater mapping, and other high-intensity acoustic applications.

An acoustic lens that could generate sound bullets was first demonstrated in 2009 by Professor Chiara Daraio and postdoctoral researcher Alessandro Spadoni at the California Institute of Technology in Pasadena, California. In that study, the researchers developed a 1D array of stainless steel spheres that struck each other similar to the way in which the metal balls in a Newton's Cradle toy strike each other. An impact at one end of the chain of spheres generates solitary waves whose speed and focal points can be controlled by controlling the properties of the device.

Now in a recent paper published in Applied Physics Letters, Daraio and a new team of researchers have expanded this 1D acoustic lens into a 2D version consisting of 13 vertical chains of 30 stainless steel spheres arranged in a square lattice. In addition, they experimentally demonstrated the ability to create sound bullets in water, which moves the technology a step closer to biomedical and naval applications. A 2D acoustic lens has two main advantages over the 1D version: the ability to control the focus in three dimensions and the potential for larger pressure gains due to the more compact arrangement.

"This work was started to move a step closer to applications," Daraio told Phys.org. "A 2D array of 'acoustic sources' (i.e., chains of particles) allow us to focus the 'sound bullets' in 3D, creating a more compact and controllable acoustic signal. This focused pressure field can then be moved (or even scanned) in a 3D volume. This is a very desirable feature in acoustic imaging and surgery, for example. Most importantly, we demonstrated the ability to produce sound bullets in water, which was something we had predicted earlier with numerical simulations, but that was never validated experimentally. Given that most acoustic imaging methods are used in a water setting (think sonars, or ultrasonic images of the human body), this is a big step forward towards a practical implementation."

The 2D acoustic lens functions similarly to the 1D version. In each chain, the 30 spheres are held in place within a hollow tube. Above the vertical chains are other elements, including compression screws and springs at the top, weights underneath them, followed by pulsers and piezoactuators that are just above the chains of spheres. The pulsers emit rapid, high-voltage pulses that exert downward pressure on the top stainless steel sphere, resulting in a solitary wave that propagates through the chain. The researchers calculated that the waves attain speeds of up to 643 m/s.

The researchers showed how, by changing the placement of the chains and the wavelength of the solitary waves, they could control the shape and size of the sound bullets. The focal point of the sound bullets could be controlled in three dimensions by changing the pre-compression applied to the individual chains, or by triggering signals in each chain with a slight time delay. Controlling these properties of the sound bullets is essential for applications, such as for high-intensity forced ultrasound for therapeutic applications in which unhealthy tissue is targeted, while damage to healthy tissue is prevented.

"The next step we would like to achieve is the ability to 'image' objects under water using sound bullets," Daraio said. "This will require smaller improvements on the experimental setup and a bit more work on the data acquisition/image reconstruction analysis. We are also working on miniaturizing the systems, in order to obtain higher focal resolution, while maintaining a good signal amplitude (which is expected to improve the signal-to-noise ratio in imaging applications, for example). Finally, we are testing the acoustic lenses in solid materials (for example, composite plates used for aeronautical applications) to use the sound bullets to detect defects and analyze the properties of adjacent materials."

More information: Carly M. Donahue, et al. "Experimental realization of a nonlinear acoustic lens with a tunable focus." Applied Physics Letters 104, 014103 (2014). DOI: 10.1063/1.4857635

Journal information: Applied Physics Letters

© 2014 Phys.org. All rights reserved.