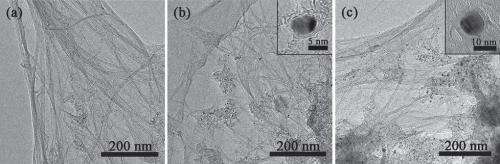

TEM images of the SWCNTs after purification for (a) 3-minute growth, (b) 10-minute growth, and (c) 30-minute growth. Inserted images show the morphology of the metal nanoparticles. An increase in the amount of metal nanoparticles can be observed for (b) and (c) compared to (a). Credit: Chen, et al. ©2013 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim

(Phys.org) —Single-walled carbon nanotubes (SWCNTs) are being widely studied for their potential applications in many areas; for example, as electrode materials for energy storage, as transparent conductive films, and as nanocomposite materials with novel properties. But all of these applications require that the SWCNTs have a very high purity, since metallic impurities have adverse effects on the nanotubes' properties. So far, preparing SWCNTs with very few metallic impurities has been challenging.

In a new paper published in Advanced Functional Materials, Professors Qiang Zhang and Fei Wei at the Beijing Key Laboratory of Green Chemical Reaction Engineering and Technology at Tsinghua University in Beijing, China, along with their coauthors, have demonstrated a method for preparing SWCNTs with a carbon content of 99.5 wt% on powder catalysts, which is one of the highest purities to date.

In general, when SWCNTs are first grown on metal-nanoparticle-supported catalysts, their carbon purity is usually around 90 wt%. Researchers can improve the purity by using new synthetic growth methods to achieve precise control over the growth process and limit the growth of metallic impurities. A second option is to try to remove some of the metallic impurities after SWCNT growth, but these methods often destroy some of the nanotubes in the process.

In most previous research, the SWCNTs are characterized before and after the growth and purification processes are performed, but very few studies monitor what happens during these processes.

In this study, the scientists used a thermogravimetric reactor connected to a mass spectrometer for in situ monitoring of the growth rate of SWCNTs grown on metal catalysts for 30 minutes. The data showed that the growth rate increases rapidly during the first 27 seconds, then slows down and is almost terminated at around 2 minutes. After that, the mass increases only very gradually.

This monitoring reveals that the SWCNTs are effectively finished growing at 2 minutes, and then metallic impurities continue to grow to the detriment of the SWCNT purity. By reducing the growth duration from 30 to 2 minutes, the scientists showed that they could improve the purity of the SWCNTs from 90.4 to 98.5 wt%.

Under the guidance of in situ monitoring, the scientists could further improve the purity using a post-growth technique. They showed that CO2 oxidation at a specific temperature (850 °C) could efficiently remove metallic nanoparticles while the SWCNTs are preserved. Consequently, very few carbon nanotubes are destroyed in this method, while the purity increases to 99.5 wt%.

"In situ monitoring of the working catalysts is extremely important," Zhang said. "The information from the working catalysts indicated the success for the preparation of high-purity CNTs. It lies in the efficient growth of CNTs with a low amount of nanocarbon impurities and partial oxidation of metal@carbon shells by catalytic CO2 oxidation with proper operation parameters. Such understanding is quite helpful to design the route for mass production of CNTs with high purity."

In the future, the researchers plan to modify the thermogravimetric reactor for additional characterization techniques, such as Raman spectrometry or X-ray diffraction, to gain further insight into the dynamics of SWCNT formation. They also expect that the approach can be applied to other systems that involve catalytic reactions with production deposition.

More information: Tian-Chi Chen, et al. "In Situ Monitoring the Role of Working Metal Catalyst Nanoparticles for Ultrahigh Purity Single-Walled Carbon Nanotubes." Advanced Functional Materials. DOI: 10.1002/adfm.201300614

Journal information: Advanced Functional Materials

© 2013 Phys.org