Arylamine functionalization of carbon anodes for improved microbial electrocatalysis

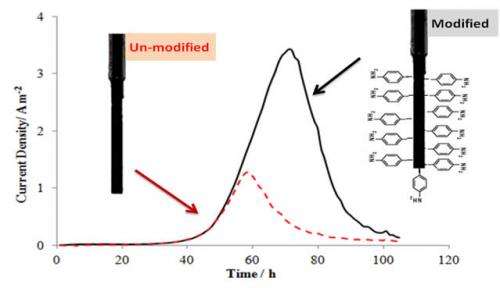

Introduction of arylamine functional groups to graphite electrodes results in improved initial catalysis for acetate oxidation by microbial biofilms over that observed on unmodified anodes. Arylamine modified anodes achieve a current density of 3.4 A m−2 whilst unmodified anodes achieve only 1.3 A m−2 during the first batch feed cycle. The surface functionalization strategy provides a route to enhancing microbial bioelectrochemical systems process performance and for studying the complex mechanisms involved in such systems.

In microbial bioelectrochemical systems (BES) a range of materials and microbes are selected on the basis of their ability to exchange electrons. However, the relatively low current densities, and long start-up times, for such systems to date points to a requirement for a more efficient connection of microorganisms, as biocatalyst, to electrode surfaces, in order to progress to exploitation of microbial BES technology. Deliberate, controlled modification of electrode surfaces provides a route to probe, and further understand electron exchange mechanisms between bacteria and electrode and may lead to enhanced performance of BES for practical applications. Introduction of arylamine functional groups to graphite electrodes resulted in improved initial catalysis for acetate oxidation by microbial biofilms over that observed on unmodified anodes. Arylamine modified anodes achieve a current density of 3.4 A m–2 whilst unmodified anodes achieve only 1.3 A m–2 during the first batch feed cycle. The surface functionalisation strategy provides a route to enhancing microbial bioelectrochemical systems process performance and for studying the complex mechanisms involved in such systems.

Overall, these preliminary results show that surface engineering (chemical functional groups) of anodes can enhance initial current density in a batch fed single chamber electrochemical cell, resulting in a slight decrease in start-up time when feeding was switched to continuous. Surface engineering is a good strategy to modulate reactor start-up (colonization time), biofilm speciation, and current output of microbial electrochemical cells and provides an additional, key, tool to improve the understanding of bacterial attachment, colonization and growth at electrode surfaces.

The work was done at BERL-Lab Bimolecular Electronics Research Laboratory (National University of Ireland, Galway).

More information: Exploring and Exploiting the Depths of the Microbial Biosphere, July, 2013, Mount Holyoke College, South Hadley, MA pubs.rsc.org/en/Content/Articl … g/2013/RA/c3ra42953a

Provided by National University of Ireland, Galway