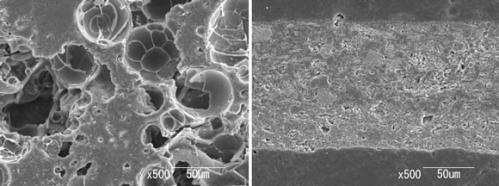

An enlarged view of conventional heat insulating paints using hollow beads (left); An enlarged view of the developed heat insulating paint using irregular silica (right).

Researchers from the National Institute of Advanced Industrial Science and Technology (AIST) have developed a heat insulating paint of a new type with irregular silica. Basic experiments were conducted to use the paint for safety management of chemical substances.

Most of conventional heat insulating paints contain hollow beads or spherical beads. On the other hand, because the developed paint uses inexpensive irregular silica particles 1-4 micrometers in size, the material cost will be reduced. The developed paint deteriorates less than any other conventional paints when exposed to heat and a paint film 0.2 mm in thickness exhibits a heat insulating effect.

The researchers confirmed that the developed paint has a good heat insulating effect when it is applied to shipping containers. By using it together with a ventilator, one can avoid inside dew condensation and thus packaging of freight can be reduced. The researchers also confirmed that the surface temperature of an oil tank became more than 10 degrees lower when this paint was applied to the top of the tank. It is expected to be easier to handle chemicals which need to be stored at low temperature.

Heat insulating paints are mainly recognized as tools for lowering the inside temperature by applying to building surfaces and reducing the amount of energy consumed by air conditioners. There were only few attempts to use them for safety management of chemical substances.

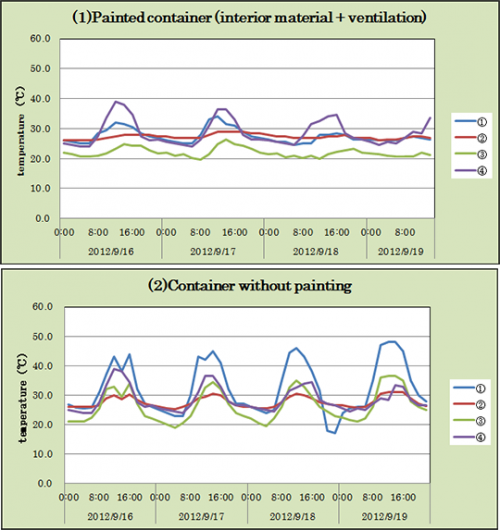

Figure 1 : The results of the experiment on the thermal insulation and dew condensation of containers using the newly developed heat insulating paint. Measurement (1) painted container (interior material + ventilation); Measurement (2) container without painting. ①The temperature inside the container, ②the surface temperature of the bucket, ③the dew point, ④the temperature outside the container.

Adequate temperature control of shipping containers was necessary for transport of chemical substances with the risk of ignition or explosion, and shipping costs for volatile chemicals were expensive. There was also a problem of inside dew condensation due to the temperature increase, resulting in unwanted influences to the freight. Thus, the development of a high-performance heat insulating paint that can solve these issues has been expected.

AIST is conducting comprehensive research on prevention of ignition/explosion disasters of chemical substances. For transport standards and classification tests of dangerous goods recommended by the United Nations, AIST has provided improved ways of testing to an expert committee of the United Nations. AIST has also conducted demonstrative experiments on safe packages for explosives. At the same time, n-tech has developed a new type of heat insulating paint using irregular silica and had been searching for its uses. They have been conducting demonstrative experiments jointly towards safety management of chemical substances.

An experiment on the heat insulating paint applied to shipping containers, with the supposition of transporting volatile chemicals, was conducted in September 2012. Two types of dry containers, (1) a dry container with the developed heat insulating paint, interior material, and a ventilator and (2) a dry container with ordinary coating, without a ventilator, as a control, were used in the experiment. As a model for the transport of a chemical substance, a sealed plastic bucket with 70L of capacity and 63L of water inside was used. A thermometer was placed on the side of the plastic bucket to measure the surface temperature of the bucket. The researchers compared it with the temperature inside the container, and the dew point, predicting whether dew condensation emerges or not.

The result was that no substantial difference in average temperature of the bucket surface was recognized, however the temperature of water in (1) was more stable than that in (2). The heat insulating effect of the paint was confirmed by comparing the temperature inside the container and outside temperature. These results imply that the shipping cost of volatile, dangerous chemical substances can be reduced. By using the newly developed paint together with ventilators can avoid the emergence of dew condensation (fig. 1) and thus prevent deterioration of the freight. The excess packaging of the freight can be eliminated, since there would be no dews. It is expected that reefer containers which has cooling facilities are not required to transport some chemical substances because the temperature will be lower than the temperature at which the heat/temperature management of the substances is necessary.

Figure 2 : The difference in temperature at parts with and without the heat insulating paint.

The researchers measured the surface temperature of an oil tank's roof, comparing the temperatures of parts with the developed paint applied, and parts without the paint. This experiment was conducted in the late September of 2012. The result was that the surface temperature of the part with the heat insulating paint was more than 10 degrees lower than that of the part without the paint (fig. 2).

With this result, it would be possible to suppress the temperature rise inside tanks and to reduce the amount of liquid nitrogen used for cooling inside. Also, from the result of the first experiment it is possible to flatten the temperature change even if the sudden whether change such as a thunder rain occurs.

Provided by Advanced Industrial Science and Technology