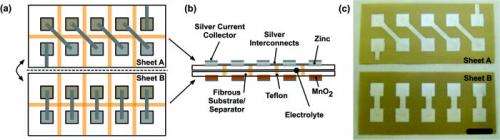

Printed Flexible Zn-Mno2 Battery. Credit: A. Gaikwad et. al. Applied Physics Letters Vol 102 Issue 23

(Phys.org) —The market for thin, flexible, printed electronic circuits is potentially huge. Although tremendous advances have been made in printing organic semiconductors like thin-film transistors (TFTs), one of their present limitations is a relatively high operating voltage requirement. 3D printed lithium-ion batteries with acceptable single-cell potentials (~3V) have been previously demonstrated, at least on small scales. The main concerns though, are that even with hermetic packaging, the raw materials for these cells still pose inherent safety and reliability risks. For wearable devices, which are a major application for flexible printed devices, a more versatile technology has been sought. A new study in Applied Physics Letters describes recent experiments with a different battery chemistry—Zn-MnO2. Using special fabrication techniques, a 10-cell series configuration of the battery was able to generate peak voltages of 14 volts, and a capacity of up to 0.8 mA h.

The main incentive to developing printed thin-film batteries is that they would be able to be fabricated on the same production line as the rest of a printed electronic device. Much research has gone into reducing the relatively high potential (10-30V) of solution-phase printed organic TFTs. The fact remains that a lot of the traditional problems of these devices like low mobility, large channel lengths, drain-source shorting, and thick dielectric layers, go away when higher voltages are used. The ability to now make high-potential batteries based on alkaline chemistry, like the Zn-MnO2, removes many of the traditional concerns with lithium batteries.

Alkaline batteries are generally less expensive than lithium batteries, and their environmentally friendly raw materials do not need to be hermetically sealed. The cells are printed on commercially available polyvivyl alcohol/cellulose(PAC) membranes. The 100um thick membrane also serves as a separator and a substrate for the Zn and MnO2 electrodes. A hydrophobic fluoropolymer solution (Teflon AF) is printed between the electrodes to reduce electrolyte migration and conduction between neighboring electrodes of different cells. The anode and cathode are printed from solution-based inks composed of conductive additives and binder materials. The cells were connected with a printed silver-based ink.

The anode and cathode footprint of the battery, as well as their separation distance, is 1 cm2. The open circuit potential of 14 V is limited mainly by self-discharge of the MnO2 electrode during processing, particularly as a result of the multiple baking steps needed to evaporate solvents. The battery was tested by discharging through a 100 kΩ resistive load. After 7.5 hours, the potential dropped to 10V, which was what was used for the conservatively-set 0.8 mA h capacity.

To further characterize their battery, a technique known as electrochemical impedance spectroscopy was used to determine the ohmic resistance (1.20 Ω), and the charge transfer resistance (0.8 Ω). These values are low enough for the individual cells that they do not cause major impedance losses when assembled into a 10-cell device. The researchers also gave the battery a real-word test to demonstrate its performance within an actual printed circuit. They used a ring oscillator circuit made from five simple inverting gates connected head-to-tail. The frequency of an output tap on this circuit depends on supply voltage and delay through the circuit.

The ring oscillator test circuit only drew a very low current and the resulting waveform peaked at 13 V on each 10 ms cycle. After 20 minutes of use, no changes in the open circuit potential were detectable, suggesting that simple circuits could be powered for an extended duration. More complex circuits may likely draw much more power than a ring oscillator, but the new Zn-MnO2 battery looks like it will be a good alternative to lithium for many foreseable printed device applications.

More information: A flexible high potential printed battery for powering printed electronics, Appl. Phys. Lett. 102, 233302 (2013); dx.doi.org/10.1063/1.4810974

Abstract

Mechanically flexible arrays of alkaline electrochemical cells fabricated using stencil printing onto fibrous substrates are shown to provide the necessary performance characteristics for driving ink-jet printed circuits. Due to the dimensions and material set currently required for reliable low-temperature print processing of electronic devices, a battery potential greater than that sourced by single cells is typically needed. The developed battery is a series interconnected array of 10 low resistance Zn-MnO2 alkaline cells, giving an open circuit potential of 14 V. This flexible battery is used to power an ink-jet printed 5-stage complementary ring oscillator based on organic semiconductors.

Journal information: Applied Physics Letters

© 2013 Phys.org