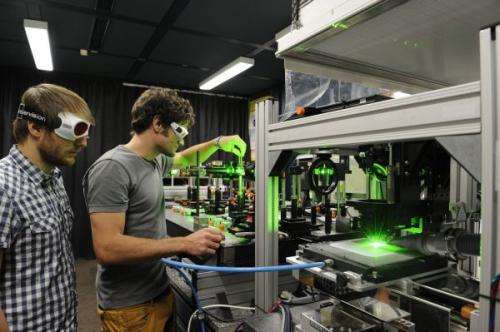

Credit: 31_laserlabor2

Photovoltaic systems are indeed enjoying a boom worldwide, yet the situation for German manufacturers of solar cells and module is critical. The reasons for this are worldwide excess capacities and manufacturers from China who have flooded the world market with modules with approximately 15 % efficiency at dumping prices. German and other European manufacturers will only be able to keep up if they are able to offer cells and modules with higher degrees of efficiency at competitive prices. The Institute for Photovoltaics (ipv) at the University of Stuttgart has now set a new record in the hunt for the highest degrees of efficiency using the simplest possible production processes. In a project funded by the Federal Environmental Ministry, success was achieved in manufacturing cells from crystal silicon with almost 22 % efficiency.

The secret of success lies in a laser process developed at the institute with which it is possible to manufacture rear side contact cells without any masking steps whatsoever. This means that only almost half of the process steps are necessary that were required up to now in the industrial production of such cells.

Prof. Jürgen Werner, Manager at the Institute for Photovoltaics at the University of Stuttgart: "We now have 22 % cell efficiency. Now the 23 % mark must be attempted, however especially the implementation in industry. The cell process should be able to be implemented in production relatively quickly."

Standard silicon cells have front side contacts made of silver. These metal fingers obscure parts of the cells and reduce their efficiency. In contrast, "rear side contact" solar cells have no contacts on the front side; all contacts are on the rear side. This solar cell type, however, requires a very fine structuring of the doping and contacting of the rear side. Usually to manufacture the fine structures elaborate and expensive masking steps are then necessary. Through the laser process, these steps are no longer necessary: it enables the manufacturing of the various doping procedures with a resolution below three hundredth of a millimetre.

Provided by University of Stuttgart