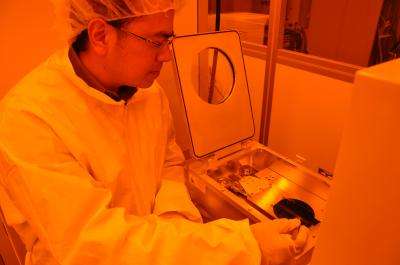

Masaru Rao, University of California, Riverside, an assistant professor of mechanical engineering, works in a clean room at UC Riverside. Credit: Sean Nealon

While automotive and medical device manufacturing may seemingly have little in common, the latter has long benefited from advancements in the former. For example, manufacturing techniques originally developed for increasing the wear resistance of metallic camshafts now find routine use in hip implants. In both applications, performance and reliability are enhanced by increasing the strength of a metal part's surface. Now, an engineer in the Bourns College of Engineering at the University of California, Riverside seeks to extend this concept to micro- and nano-scale medical devices.

Masaru Rao, an assistant professor in the Department of Mechanical Engineering, recently received a five-year, $400,000 Faculty Early Career Development (CAREER) award from the National Science Foundation, which, as one of its primary objectives, seeks to explore potential for strengthening miniaturized medical devices made from titanium.

A key enabler for this effort is an innovative manufacturing technique Rao helped pioneer nearly a decade ago, which allows machining of titanium at an unprecedentedly small scale. Similar to techniques used in integrated circuit manufacturing, this emerging micromachining process relies on plasma to sculpt titanium-based devices with micro- to nano-scale dimensions. This provides a particular opportunity in the biomedical realm, since it allows fabrication of miniaturized medical devices using a material with well-proven biocompatibility in chronic implantation applications.

Building on this unique manufacturing capability, Rao's new study will focus on developing techniques for strengthening tiny titanium-based medical devices, since this could lead to significant improvements in their performance and reliability. Interestingly, while nearly all macro-scale metallic parts in use today rely on some form of strengthening (e.g. alloying), there has been minimal use of strengthening for micro- and nano-scale devices thus far. According to Rao, "this is due, in large part, to limitations imposed by the micromachining techniques that must be used to access these reduced length scales."

For example, Rao's own technique only works with pure titanium, due to the highly chemical nature of the material removal mechanism upon which it is based. This, therefore, precludes opportunity for using it to micromachine other high strength biomedical alloys (e.g. stainless steel), or even high strength titanium alloys, since all contain additional metallic elements that adversely affect the micromachining process. Moreover, while coating of machined parts to increase their hardness is commonplace that the macro-scale (e.g. titanium nitride coated drill bits), this is severely constrained at the micro- and nano-scale by challenges associated with maintaining coating uniformity and quality over complex device structures.

To address these limitations, Rao will explore use of gas nitriding, a nearly century-old technique that is used widely for increasing the wear resistance of macro-scale metal parts for automotive and other applications (e.g. case hardened engine camshafts and rifle firing pins). In this technique, the surfaces of machined parts are strengthened by heating them in a nitrogen atmosphere, which causes nitrogen to diffuse into the metal. When applied to titanium parts, the nitrogen atoms tend to squeeze into the spaces between the titanium atoms, thus forming a nitrogen-based titanium alloy. The presence of the nitrogen atoms makes it more difficult for the titanium atoms to rearrange themselves in response to mechanical loading, which leads to significant strengthening. However, the relatively slow diffusion of nitrogen within the titanium means that strengthening is typically limited to the near-surface region (i.e. a few tens of micrometers at most), and the concentration of nitrogen decreases with depth.

Nevertheless, Rao thinks that this technique holds significant potential for miniaturized medical devices. "While pure titanium has adequate strength for many applications, device performance and reliability could be enhanced significantly if we can increase strength. Gas nitriding may provide a means for doing so, since it can be applied to our devices after they have been fabricated, it won't suffer from the limitations of coating-based processes, and the diminutive dimensions of our devices will make it easy to diffuse nitrogen throughout the entire structure, thus allowing through-thickness strengthening." However, Rao indicates that the translation of this technique to his devices won't be as simple dropping them into a conventional nitriding furnace. "There are potential tradeoffs unique to the micro- and nano-scale that need to be better understood to assess feasibility."

For example, while diffusion of a small amount of nitrogen into titanium can yield significant increases in strength, it doesn't take much to overdo it, due to the limited amount of space available between the titanium atoms. When this concentration threshold is surpassed, titanium nitride intermetallic compound begins to form. Although titanium nitride is far harder than titanium, its presence is often undesirable, because its brittleness can adversely affect strength and fatigue resistance. At the macro-scale, this is typically dealt with by grinding the surface of nitrided parts down to a sufficient depth to remove the brittle titanium nitrade layer, thus revealing a surface that contains just enough nitrogen for strengthening. This is not an option for tiny titanium devices, however, due to the lack of such material removal capability at micro- and nano-scale. "Consequently, the key here will be to precisely control the diffusion of nitrogen into the titanium surface, to ensure that its concentration is kept below the threshold for titanium nitride formation. This will be a challenge, particularly for structures with such small dimensions."

To illustrate the need for such precision, Rao points to a separate project currently being undertaken in his lab that is focused on developing titanium-based microneedle devices for minimally-invasive drug delivery. Microneedles are micro-scale penetrating structures that are, in the simplest sense, highly miniaturized versions of the hypodermic needles that most everyone has had to endure at some point in their lives, whether it be for an immunization or a Novocain shot at the dentist. The diminutive size of microneedles provides opportunity for significantly reducing damage during tissue penetration, which may ultimately lead to reduced healing time and increased device performance. In collaboration with Malik Kahook, a professor in the Department of Ophthalmology at the University of Colorado, Rao has been exploring potential for developing microneedles for delivering drugs to the eye

"Since these devices are intended for penetration of relatively robust but also highly sensitive tissues, such as cornea and sclera, strength is crucial," Rao said. "Increased strength will allow us to make smaller devices, which will reduce tissue trauma and insertion force, both of which are important performance metrics." While gas nitriding may provide means for achieving such strengthening, precise control of nitrogen diffusion into the devices will be required to ensure that titanium nitride formation does not occur, since it will be impossible to remove this material from the surfaces of these highly complex devices after nitriding.

Another potential tradeoff of the gas nitriding process is the adverse affect this will have on ductility, the capability of a material to accommodate significant stretching without tearing apart. This is because the same constraint of titanium atom movement that produces strengthening also reduces the extent to which the material can be stretched prior to failure. According to Rao, this won't be a problem for most applications they are pursuing, since the expected deformations are small. However, for some applications, addressing this issue will be paramount.

As an example, Rao points to yet another project in his lab that is seeking to develop vascular stents that use nano-scale surface topography to enhance healing after implantation. Stents are millimeter-scale scaffolds that are used to prop open arteries clogged by plaque buildup. While stents have been in widespread use for more than a decade, a small percentage of patients receiving such devices still suffer from serious complications that arise from incomplete healing of the vessel around the stent.

In collaboration with Victor Rodgers, a professor in the Department of Bioengineering at UCR, Rao has been exploring potential for reducing such complications through the creation of precisely-defined, nano-scale structures on the surface of titanium-based stents that may accelerate the healing process. "Early on, one concern was that these tiny surface structures would be susceptible to damage, since they're subjected to abrasion during deployment of the stent. We believe that gas nitriding may provide means for increasing the strength of such structures as well, thus increasing their resistance to damage. However, since stents must endure significant deformation during their deployment, precise control of N diffusion will again be the key here. We want to strengthen just deep enough to protect the surface nanostructures, but not any further, since this will compromise the ductility of the underlying titanium.

Provided by University of California - Riverside