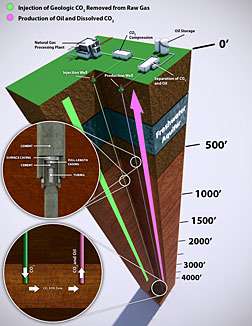

Three layers of steel (casing and tubing)and two layers of durable, long-lasting cement separate the contents from the surrounding groundwater.

Geologic carbon storage is the separation and capture of carbon dioxide (CO2) from large stationary sources, such as power plants, followed by injection into deep geologic formations. Long-term storage of CO2 pre-supposes very low or no leakage from the formation. The majority of locations that are being considered for CO2 injection are in areas that have a history of oil, natural gas, and/or coalbed methane production, and are typically penetrated by a significant number of wells from exploration and production. The ability to effectively store large quantities of CO2 may be compromised by the presence of these active or abandoned wells, which represent potential leakage paths.

Once an oil or gas well is drilled, it is typically lined with a steel casing cemented into place. The cement is placed in the annular column (the annulus) between the casing and the surrounding rock formation to support the steel casing and to prevent the flow of fluids and gases along its outside diameter. When a well is ultimately abandoned, the casing is typically plugged with cement to block vertical migration of fluids. Cement is not stable in a CO2 environment and can be vulnerable when a wellbore is exposed to CO2 injected into the surrounding formation for permanent storage. The integrity of cement has important implications for the long-term fate of CO2. As a result, DOE's National Energy Technology Laboratory research has focused on the integrity of wellbore cement when contacted with injected CO2 under storage conditions. This entails simulating deep underground injection and wellbore conditions such as high temperatures and pressures using common wellbore cements. Results show that temperature, pressure, cement type, cement additives, and fluid properties play a significant role in the rate of reaction and alteration.

Chemical and microstructural changes resulting from exposure to CO2 were examined using a variety of analytical techniques including scanning electron microscopy and x-ray diffraction.

Results of long-term CO2/cement experiments show that the CO2 reaction with typical wellbore cement is too slow to cause leakage in a properly constructed well in good condition, and are in excellent agreement with the examination of cement samples obtained from a well that had been exposed to CO2 for EOR (enhanced oil recovery). However, cement in old or abandoned wells that may have deteriorated could be a problem. As a result, NETL researchers are now studying situations in which gaps or fractures may be present in the cement column.

Co-sequestration, which involves injection of a mixture of CO2 and hydrogen sulfide (acid gas) is increasingly being practiced. For example, there are over 40 wells being used for acid gas injection in Alberta, Canada. In contrast to pure CO2 injection, there is little understanding of the effects of acid gas on exposed wellbore cements under geological storage conditions. Therefore, NETL researchers have initiated studies on the interaction of cement under co-sequestration conditions.

Provided by US Department of Energy