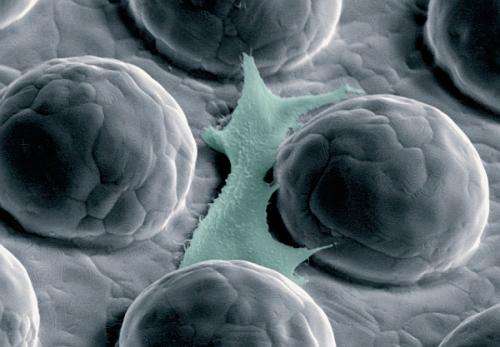

This is how cells adhere to the structured surface.

(Phys.org)—Swiss cell biologists at Empa want to "tune" implants such that they can better carry out their tasks in the human body. The surface of the implant is the key to success. Together with the Fraunhofer Institute IFAM, the Empa team developed a method to manufacture implants with the required surface "from a single cast".

In order to encourage the human body to accept an implant, its surface should be readily inhabitable by (future) neighbouring cells. Osteoblasts, i.e. cells that are responsible for bone formation, must be able to attach to an artificial hip joint so that new bone substance forms, thereby firmly anchoring the implant in the bone. Researchers at Empa are working to develop micro-structured implant surfaces that provide the bone cells with the best possible growth conditions. Arie Bruinink, cell biologist in the "Materials-Biology Interactions" laboratory, explains: "Amongst other things, we have seen that a surface structure with near cell-sized dimples has a considerable effect on cell shape and adhesion."

The scientists can observe how cells respond to different model surfaces with a confocal laser scanning microscope, amongst other things. Once the bone marrow cells had been disseminated onto a metal probe with a dimpled surface, they adhered to the material, formed their cell skeleton or cytoskeleton, and adapted their shape to the surface structure. On a surface with dimples with a diameter of 30 or 50 micrometres and 20 micrometres apart, the cells stretch between the dimples and are no longer as flat as they normally appear in a culture dish. Bruinink believes that this is a very conspicuous behaviour, the effects of which on cell differentiation should be investigated further.

Pore-free cleanliness – and still favourable

In order to manufacture implants in innovative ways, he initially developed a metal injection moulding (MIM) procedure with colleagues from the Fraunhofer Institute for Manufacturing Technology and Applied Material Research (IFAM) in Bremen. This allows the implant and its microstructured, biocompatible surfaces, to be manufactured in "a single cast". According to Bruinink, the aim of the project, financed by the Volkswagen Foundation, is to create surfaces that can be structured with (sub-)micrometer accuracy – a precision that has hardly been possible to date; it takes a considerable amount of money and effort to manufacture structures like this. During implant manufacture it is also important that no unwanted pores form on the surface, in which germs could hide. These can cause infections and chronic inflammation – with the possible consequence that the implant will have to be removed again. Bruinink is pleased with the new MIM method, since it has succeeded in creating a precisely structured, pore-free surface simply and cost-effectively.

A patented method – and not just for the medtech sector

This method, which has now been patented, is not only suitable for materials in the medtech sector. The material's outstanding mechanical properties (high density and nanostructured design) are also interesting for other applications. The method could therefore be used in almost any situation where materials with greater strength and hardness are required, such as gears and ship propellers.

This method, which has now been patented, is not only suitable for materials in the medtech sector. The material's outstanding mechanical properties (high density and nanostructured design) are also interesting for other applications. The method could therefore be used in almost any situation where materials with greater strength and hardness are required, such as gears and ship propellers.

More information: M. Bitar, V. Friederici, P. Imgrund, C. Brose, A. Bruinink: In vitro bioactivity of micro metal injection moulded stainless steel with defined surface features, in: European Cells and Materials, Vol 23, May 2012 (pages 333–347) www.ecmjournal.org/journal/pap … l023/pdf/v023a26.pdf