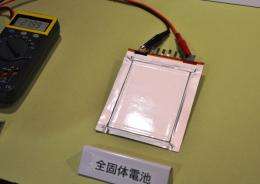

The all-solid-state battery prototype. Credit: Tech-on

(Phys.org)—It's no secret that Toyota has been hard at work trying to improve on current battery technology to power electric vehicles, last year the company described a prototype solid state lithium superionic conductor battery in an article in the journal Nature Materials that was based on a three dimensional framework. And just this month the company announced plans to introduce several new lines of hybrid and all electric vehicles over the next three years (after also announcing that the Prius hybrid now accounts for ten percent of all sales). The sticking point has been and remains, the batteries used in such vehicles which can account for up to half their cost to consumers.

At the heart of current batteries for use in electric vehicles are liquid electrolytes, which by their very nature present fire safety hazards. Adding technology to reduce the fire hazard adds to the cost of the battery, thus a battery based on a solid electrolyte would be cheaper and safer. Up till now however, such electrolytes have only been practical at the 50–80 °C range which obviously isn't workable for an electric vehicle. The new prototype is an attempt to overcome that restriction.

The new battery, first described last year, uses Li10GeP2S12 in a layered three dimensional framework where cells are sandwiched together to create a stack of seven tiers with each having a voltage of four volts for a total of twenty eight at normal temperatures. The result, they say is a battery with five times the output density of previous varieties. To demonstrate its progress in refining the battery, the prototype was demonstrated recently to a group attending a green technology seminar as a power source for an electric scooter.

The battery is sulfide based and differs from previous prototypes in that germanium was added to the mix to bring a more refined structure to the material. It boasts improved conductivity to 1 x 10-2S/cm-1, which is on a par with liquid electrolyte based batteries, though the company readily acknowledges that there is still a lot more work to do before such a battery could be used in electric vehicles for sale. They are shooting for a 2015 to 2020 timeframe, at which point, the hope is that a way will have been found to dramatically reduce production costs, which are at this point, apparently far too high to allow for use as a commercial battery.

© 2012 Phys.org