Fujitsu develops a 2.3kW high-capacity power supply unit for servers, conversion efficiency rate of 94.8%

Fujitsu Laboratories today announced the development of a power supply unit for servers that features a 2.3 kW power output and achieves a world-leading conversion efficiency rate of 98.4%.

As servers have grown more powerful, their energy requirements have increased as well, creating a need for power supply units with more capacity to supply electricity inside the server. Power supply units take externally supplied AC power (200 V AC) and convert it to DC power (12 V DC) that has been stabilized to meet the server's operating requirements. This conversion process is always accompanied by some loss, while minimizing the conversion loss and increasing power supply conversion efficiency is an important factor in reducing a server's overall energy requirements. However, greater power supply unit capacity typically results in greater internal loss, making a high-efficiency power supply unit difficult to produce.

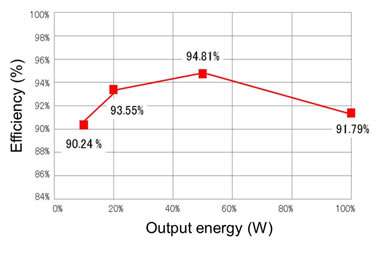

Fujitsu Laboratories has developed digital control technology and new circuitry aimed at reducing power supply loss in order to achieve a world-leading 94.8% conversion efficiency rate with the 2.3kW high-capacity power supply unit., This reduces overall energy requirements for the server and contributes to energy savings for datacenters.

The difference between input energy and output energy is referred to as power supply loss, and is given off as heat by the power supply unit. The ratio of energy output to energy input is called the power supply unit's efficiency. Reducing this loss—in other words, increasing the power supply unit's conversion efficiency— is an important factor in reducing a server's overall energy requirements. Enterprise servers, blade servers, and other high-performance servers consume dozens of kilowatts of electricity, so when using multiple high-output power supplies, the loss alone amount to several kilowatts.

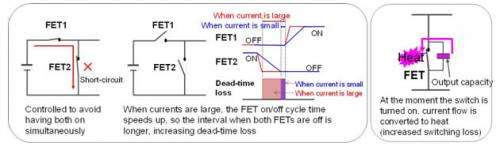

A power supply performs voltage conversion with field-effect transistors (FET), which are cycled on and off. As the power supply unit's capacity increases, the loss that accompanies on/off switching in the power supply's FETs also increase, making high-efficiency power supply units that much more difficult to produce.

1. Dead-time loss

To avoid shorts, a power supply unit's circuitry will control one FET to cycle on shortly after another FET has cycled off (Figure 1, left). In a conventional power supply unit, this interval is fixed, but with large currents, each FET's cycling speeds up, causing a longer interval when neither FET is on, which increases loss (called "dead-time loss").

2. Switching loss

In high-capacity power supplies, larger FETs (the switching elements) are used to prevent voltage drops and heat generation, which in turn requires lower resistance when on. But with larger FETs, because they have higher than normal output capacitance, the current loss at the moment when the FET is switched on (switching loss) is greater (Figure 1, right).

Fujitsu has developed digital control technology that reduces dead-time loss, and a new circuit technology that reduces switching loss. Features of these technologies are as follows.

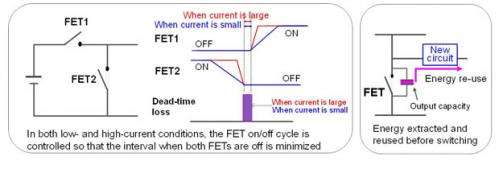

1. Digital control technology to reduce dead-time loss

Fujitsu Laboratories developed digital control technology that adjusts the on and off intervals for two FETs. As the FET's cycle speed increases with larger currents, the periods when both FETs are off tend to be longer, increasing the dead-time loss. To prevent this from happening, the time when the second FET switches off is delayed, while the first FET is turned on more quickly. This makes it possible to minimize the interval that both are off, as when there is a small current, which reduces dead-time loss (Figure 2, left).

2. New circuitry to reduce switching loss

The company developed a new type of circuit that reuses energy stored in a FET's internal output capacitance. By extracting the energy collected in the output capacity before the FET switches on, this new circuit can reduce switching loss (Figure 2, right). Details of this technology were presented at the Power, Electronics, Machines, and Drives Conference (PEDM) 2012.

Using these technologies, Fujitsu built a prototype 12V, 2.3 kW maximum output high-capacity power supply for servers that achieved a world's-best conversion efficiency rate of 94.8% (figure 3). Not only does this technology directly reduce loss, but by suppressing the production of waste heat, it reduces energy needed for fans to cool the power supply unit, and allows the power supply unit to be more compact. By reducing a server's energy demands, this can contribute to greater overall savings for datacenters.

Work is proceeding on further improving the efficiency, reliability, and consistency of these technologies with an eye toward debuting servers equipped with power supply units using these technologies in 2014.

Source: Fujitsu