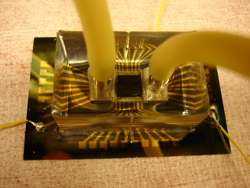

The demonstrator photo (provided by FOAB) shows the micro-cooler device is running, and thermal energy is taken away by the coolant flowing through the micro channels. © Yifeng Fu

At first glance, supercomputers, car parts, entertainment systems and radar antennas may not have much in common, but they all stand to benefit from important advances in thermal management technology being achieved by an EU-funded project. Materials developed under the project have been demonstrated in different application sectors, and some are already in use commercially, or likely to be in the near future.

Improving thermal management is essential if processing power is to continue increasing as electronic components get ever smaller. Too much heat that can't be managed effectively puts limits on the performance of chips and other microelectronic components, it reduces reliability, and it also costs money and harms the environment.

A prime example of the problem from a technical, environmental and economic perspective are data centres. These vast buildings - sometimes spreading across the equivalent of several football pitches - are used by a variety of industries to store and process data. The banks of computers inside them produce a lot of heat. So much in fact that around half the cost of building a new data centre goes on the cooling system, which in turn requires more energy to operate, resulting in a large carbon footprint.

The same problems are true in any industry that uses microelectronics - from telecommunications to aviation. Hence demand for a better solution is intense. In Europe, companies such as Thales, Bosch and IBM have joined up with research institutes and universities, obtaining funding from the European Commission to try to develop new materials and processes to solve the thermal management issue.

Their efforts in the 'Nano packaging technology for interconnect and heat dissipation' (Nanopack) project have resulted in new 'Thermal interface materials' (TIMs) developed with micro- and nanotechnology to greatly increase heat transfer away from chips and other electronic components, in turn reducing the demands placed on cooling systems, lowering costs and reducing energy consumption. The materials have been showcased in a series of demonstrators with applications across a variety of sectors, some of which are in use commercially or are likely to be in the near future.

'At Thales, we build radar systems for airplanes. Thermal issues are especially important in that environment because the space available is very small and very confined. At present, the cost of the thermal architecture of the radar is something like 40 % of the total cost,' says Afshin Ziaei, a manager of research at Thales Research & Technology in France.

To address that problem, the Nanopack researchers developed prototype high-power amplifiers, thousands of which make up the active phased array antennas of an aircraft radar system, using new materials developed in the project. By applying specially designed thermal conductive greases and adhesives containing nanoscale micro-fillers between the chips in the amplifiers and their surrounding packaging, the team are improving heat transfer without the need for additional cooling.

Other, more experimental, technologies are also being tried out with the amplifiers, including tiny carbon nanotubes oriented vertically in a solution so heat is transferred upwards through the centre of the tube.

For Thales Avionics, the Nanopack team worked on better thermal management for in-flight entertainment systems, which use a so-called 'Seat electronic box' (SEB) placed under each passenger's seat on modern aircraft to store and manage the movies, music, games and other entertainment features shown on their personal screen.

'This is another example of the problems of having electronics in a small, confined and enclosed space with limited cooling possibilities - it is a real challenge to dissipate the heat in that environment,' Mr Ziaei notes. 'We are using a heat-pipe with the micro-filler grease as a thermal interface to transfer the heat from the components to the SEB and from the SEB to an external heat sink.'

The team is also considering another technology for the demonstrator: a polymer fibre network infiltrated with a metal alloy that somewhat resembles a very fine sheet of aluminium foil and which tests show transfers about twice as much heat as the grease or adhesive.

For Bosch, the Nanopack team is also using grease and adhesive to reduce the heat build-up from the transistors in a power amplifier module from a commercial electrical power steering unit used in cars.

'In this case, better thermal management means the unit can operate at higher temperatures and perform better, or it can operate at the same temperature with increased reliability,' the project manager says.

IBM, meanwhile, is using materials and techniques developed and advanced in Nanopack on high-performance microprocessors. Grease and a technology known as 'Hierarchical nested channel' (HNC), which uses microstructures to improve conductivity, have since been employed by IBM in its Aquasar Supercomputer which, thanks to a unique cooling system, has an 85 % smaller carbon footprint than comparable systems.

By ensuring that their materials and processes are compatible with high-volume manufacturing techniques, the team has focused not just on research and development but also created materials and processes that are likely to find their way into commercial products and systems in the very near future. In that vein, they also worked on the very important area of materials characterisation, attempting to set a benchmark for testing the thermal conductivity of materials so that their properties are clear to all.

'At the start of the project, we did a blind test and sent the same test materials to all the partners for them to measure with their own characterisation methods. We found that the difference in the results varied between 50 and 100 %. Now, at the end of the project and with the characterisation tools and methods we developed, the error band has been brought down to within a much more acceptable 20 %,' Mr Ziaei says.

Similarly, three-dimensional design simulations of materials can provide important insights into material properties before, during and after development. Swedish partner FOAB, for example, used its simulation tools to demonstrate how a chip can be cooled with a heat sink built of carbon nanotubes.

'With this, we are able to simulate the heat transfer beforehand at both the component and the system level,' Mr Ziaei notes.

Some of these characterisation and simulation tools are to be commercialised by the project partners.

Provided by CORDIS