February 15, 2011 weblog

Toyota shows off its new iQ electric-car prototype

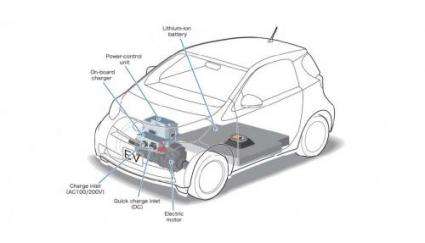

(PhysOrg.com) -- The Toyota Motor Corporation is set to show off its EV car, an electric-car prototype version of Toyota's iQ model, at the Geneva auto show next month.

The EV prototype car will have an electric powertrain that is based on the current Toyota Hybrid Synergy Drive system. This system will feature a flat lithium-ion battery pack which, according to Toyota, will be able to give the car a driving range of up to 105 kilometers, or about 65 miles, on a single charge. Obviously, the car is built for short-range transportation, and not for use on longer trips, which is a common issue with electric cars.

This is a preview only, since sales of the car will not begin until an as-yet-unspecified date in the year 2012. At first, the EV is likely to be available in Europe through a leasing plan, once it finishes its road testing, which will also be done in Europe. The car will also be available in North America, and some other markets which are currently being investigated for their viability.

The car is slated to fit three passengers, which makes it smaller than both the Mitsubishi i-MiEV and the Nissan Leaf, two currently popular electric vehicles. This is, of course, not Toyota's only attempt to make an electric vehicle. They are also working with Tesla Motors Inc. to create an electric version of the RAV4 compact SUV which is also planned to be released in 2012. Several other vehicles are in the works for the future, but they have much longer wait times, such as the sedan-type fuel-cell hybrid vehicle expected to launch in 2015 in Japan, the U.S. and Europe.

© 2010 PhysOrg.com