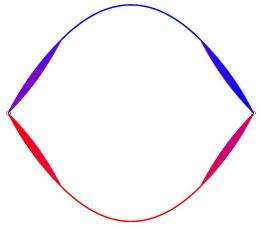

Forms found to be more optimal than a parabola to carry a uniform load between pinned supports (compressive elements shown in blue). Image credit: Matthew Gilbert

(PhysOrg.com) -- A team of structural engineers from the University of Sheffield in the UK say the assumptions originating with 17th century Dutch engineer Christiaan Huygens may need to be re-examined. Huygens assumed the best design for a suspension bridge was based on towers and simple cables hanging between them to support the weight, but the Sheffield group say a more complex design using less material would be more efficient.

The Huygens idea is behind well-known suspension bridges such as the Golden Gate bridge in San Fancisco and the Akashi-Kaikyō Bridge in Japan, which is around 700 meters longer. Basically, the road or railway is suspended from thin hangers dropping from two cables that stretch between the two towers. The cables automatically form a U-shaped curve, or parabola, and this arrangement has been assumed to be the most efficient.

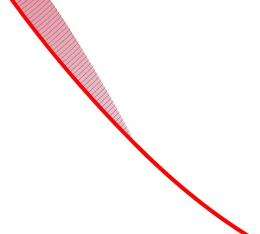

Matthew Gilbert and his colleagues from the Department of Civil and Structural Engineering noted that the calculations assumed the cables could withstand tension but not compression, but in reality both forces are in play. They developed a numerical layout optimization program to check the optimal design and were surprised to find Huygens' parabolic arch rib or cable was not optimal, and the amount of material needed for the cabling could be reduced if the ends were replaced with a network of truss bars known as the "Hencky net". Gilbert said they expected the parabolic design to be confirmed and they tried to work out what was wrong when their software continually nominated the more complex design. "It ended up that the only option was that the current wisdom was wrong," Gilbert said.

The amount of cable that can be replaced depends on the level of compression the material can withstand. If it can take tension and compression to an equal degree, using a net can reduce the amount of material needed to build the bridge by 0.3%. Other structural engineers have pointed out that this small reduction in material may not provide an economic justification for making a more complicated bridge, since they would undoubtedly be more expensive to manufacture.

The work is published in the January edition of the Structural and Multidisciplinary Optimization journal.

More information: Optimum structure to carry a uniform load between pinned supports, Structural and Multidisciplinary Optimization, www.springerlink.com/content/v4543505v4721655/

© 2010 PhysOrg.com