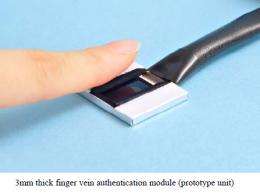

Hitachi, Ltd. today announced the development of a 3mm thick thin-type finger vein authentication module. Finger vein authentication is a biometric identification technology which employs near infrared light to observe finger vein patterns.

The significant decrease in thickness of the finger vein authentication module was achieved through the development of a new contactless flat sensor for capturing the finger vein image. Further, signal processing technology was developed to reduce interference from external light such as sunlight, in vein pattern observation to improve practicality. This development will now make it possible to employ the technology in various security applications for space restricted products such as in mobile equipment, automobiles, houses.

With the rapid development of the information society, awareness of the importance of protecting personal and confidential information is increasing in both the private and public sectors. Along with this, there is growing notice of biometric recognitions systems which are based on features unique to an individual such as fingerprint, iris, face and vein. To date, Hitachi has developed “finger vein authentication technology” based on finger vein patterns which are characterized by a high resistance to counterfeiting, and commercialized it in a wide range of products such automatic teller machines, room access control and PC log-in. This time, in order to expand the application of the technology to areas such as mobile equipment, motor vehicles and homes where spatial fitting restrictions exist, Hitachi has developed a thin-type finger vein authentication module with a thickness of 3mm.

Features of the newly developed thin-type finger vein authentication module are as follows.

(1) Technology to reduce the thickness of the finger vein authentication module

A flat sensor with a high sensitivity to near infrared light, able to capture finger vein images without contact, was newly developed. Until now, the image obtained by illumination with near infrared light was captured using a single lens camera method. As a result, there was a limit to the thinness of the finger vein authentication module due to the space required between the finger and the lens, as well as the thickness of the lens itself. In the newly developed thin-type contactless flat sensor, micro lenses with a short focal length are positioned for each pixel of the sensor enabling a focused clear vein pattern to be captured despite the proximity of the finger to the sensor, thus achieving a thinner finger vein authentication module.

(2) External light resistant signal processing technology

Signal processing technology which precisely controls the sensitivity of the flat sensor and the brightness of the light source depending on the direction and strength of surrounding external light, was developed to achieve reliable recognition regardless of changing lighting conditions. Further, narrow space finger vein image processing technology to conduct recognition when the light receptor area of the sensor is fully covered by a finger, was developed to reduce external light entering the imaging area.

Using this new technology, a finger vein authentication module with a thickness of 3mm was developed, and a thin-type finger vein authentication unit consisting of this module, and an external authentication processing component for matching the captured image with recorded image, was prototyped to confirm contactless personal identification.

Source: Hitachi