The next big thing in molecular separation

A new sieve designed by a University of Alberta graduate student could be the next big thing in separating molecules using really, really small devices.

Yong Zeng, who is working towards his PhD in chemistry, and his supervisor, Department of Chemistry Chair Dr. Jed Harrison, have published research results that demonstrate a new nano-scale sieve design that is easier and cheaper to produce, and more efficient than sieves produced by other high-tech nanotechnologies. Their findings appear in the journal Analytical Chemistry.

The sieve has potential applications in biomedical research. It will, for example, allow researchers to separate viruses from fluid or tissue samples.

The sieve Zeng and Harrison designed uses silica sand, along with the same kind of silicone you'd use to line a bathtub, to act as a filter. The devices are produced quickly, can be used hundreds of times because they have many channels, and cost no more than $10 to manufacture.

In Zeng and Harrison's design, samples flow around uniformly packed silica pellets, the way water would flow around grapes packed into a box.

Researchers can customize the sieves to larger or smaller scales, to allow larger or smaller objects to pass through. For example, marbles would filter through a box of basketballs, but tennis balls wouldn't. By adjusting the size of the silica beads in the sieve, Zeng and Harrison are able to filter out objects as small as a virus.

"What Yong has developed is a way to make ordered lattice structures that are crystalline packings of 100 - 1,000 nanometers in diameter, and the space between the beads becomes ordered," said Harrison, adding that the design allows researchers to use larger fluid or tissue samples, yielding larger result samples to study - a definite improvement over other sieve designs.

Another recently designed sieve nanofabricated on silicon/glass chips has made a big scientific impact, but is far from practical because it is costly to produce (over $1,000 each), and can only be used about 10 times before samples clog its channels.

"So from our point of view this takes the advances discovered in the silicon/glass devices and makes them commercially viable," said Harrison.

Zeng, who completed his undergraduate studies at China's Wuhan University, began working on the new design when he'd grown frustrated by the work Harrison had originally assigned him - to work on sieves made in silicon using nanolithography.

"The goals are the same, the method's different," said Harrison of the outcome. "Yong just concluded that the conventional method was too hard and too expensive."

"I was a little nervous about it," Zeng said of presenting his idea to Harrison. "And I wanted to publish a paper on this right away, but thankfully Jed said that we should refine it and improve it first. And I'm glad we did - I'm not sure it would have had the same impact."

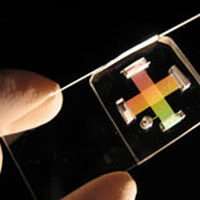

Manufactured on glass and plastic slides or "chips", the sieves measure a few square millimeters.

Harrison said the chips also have potential application in the field of photonics. The sieves could be used to manipulate beams of light shone through them as well.

Source: University of Alberta