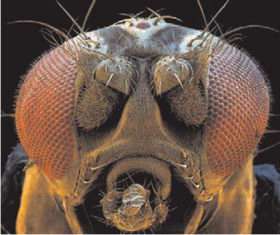

The fruit fly has apposition compound eyes, which scientists have fabricated using photolithography to arrange and tune an array of microlenses. The microlenses act as "ommatidia," the insect’s tiny eye sensors. Photo credit: IOP.

Inspired by the way that nature has evolved the eyes of small insects, scientists have fabricated artificial compound eyes that could make camera lenses tiny enough to fit on credit cards or stickers.

Today’s digital micro-cameras and other optical devices use lenses based on human-type single aperture eyes. These lenses, which are manufactured with macroscopic technology, do not get thinner than about 5 mm.

However, insects such as fruit flies and moths have a completely different type of eye called compound eyes to accommodate the animals’ small size and low brain processing capabilities. Compound eyes consist of up to tens of thousands of tiny sensors called “ommatidia” that detect light and sometimes color. Flies and moths see images made of a combination of inputs from the ommatidia that point in different directions, forming a large field of view while the total volume consumption remains small.

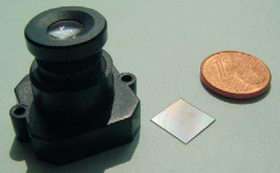

Scientists fabricated an artificial apposition compound eye (center) that is significantly cheaper and smaller than a traditional 20-mm single lens objective (left) with the same magnification; and much smaller – though not quite as cheap – as a Euro cent (right). Photo credit: IOP.

“While human eyes use a spherical volume, compound eyes use only a spherical shell, so that much of the space and weight is saved for the brain,” Jacques Duparre, coauthor with F. C. Wippermann of a recent paper in Bioinspiration and Biomimetics, told PhysOrg.com. “The arrangement allows for a large field of view, but does not require large signal processing.”

Although single aperture eyes have advantages in resolution and sensitivity in large lenses, compound eyes have the potential to make more compact, robust and cheap vision systems. At the micro level, compound eyes’ individual viewing channels on curved lenses have minimal aberrations, or focusing errors that cause blurring. Cameras with compound eye lenses could have applications in many tight spaces, such as those encountered in automotive engineering, security and surveillance, and medical technology.

“Thin lenses might have applications in flat panel displays, and we’re also working on another arrangement for minimal invasive surgery,” said Duparre, who is currently working on a patent for this arrangement.

Scientists have studied optical lenses based on natural compound eyes for more than a hundred years, but classical macroscopic technology has not provided the necessary fabrication and assembly accuracy. For the first time, Duparre and Wippermann have fabricated and tested two different compound eye lenses using state-of-the-art micro-optics technology.

To fabricate the first type of compound eye, called an apposition compound eye and found mainly in diurnal insects such as flies, the scientists used photolithography to arrange a microlens array on a thin silicon wafer. Acting as ommatidia, the microlenses could be specially tuned to improve homogenous resolution over the entire field of view. Further, the scientists found that the large focal depth of apposition compound eyes cancels the need to adjust lens focus for distant or near objects.

The second type of compound eye, found mainly in nocturnal insects such as moths and deep water crustaceans such as shrimp, have greater light sensitivity than apposition compound eyes. Comprised of an array of microtelescopes, these eyes are known as superposition compound eyes or simply cluster eyes. Using reactive ion etching to transfer the microlenses onto fused silica, the scientists fabricated cluster eyes whose individual lenses also improved resolution homogeneity. Compared with apposition compound eyes, cluster eyes require thicker objectives but offer higher resolution. Both types have potential for use in tiny cameras.

“Deciding between the apposition and cluster eyes depends on the required resolution vs. compactness vs. price,” said Duparre. “The apposition eye will be cheaper and smaller but have lower resolution. It thus will more work like an imaging optical sensor, while the cluster eye could actually be used to present images directly to a customer, but is more complex.”

These advantages of artificial compound eyes were discovered despite one major technical drawback: both types of compound eyes were arranged on a flat surface, while the curved base of natural insect eyes offer several advantages. Hopefully, a special type of laser beam writer currently being developed could fabricate compound eyes on curved surfaces.

Citation: Duparre, J. W. and Wippermann, F. C. Micro-optical artificial compound eyes. Bioinspiration and Biomimetics. 1 (2006) R1-R16.

By Lisa Zyga, Copyright 2006 PhysOrg.com