Carbon nanotubes eliminate polymer manufacturing headache

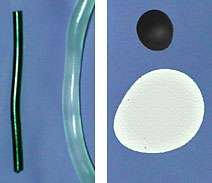

Researchers at the National Institute of Standards and Technology (NIST) have discovered that the addition of carbon nanotubes to a common commercial polymer, polypropylene, leads to dramatic changes in how the molten polymer flows. This process eliminates a widespread manufacturing headache known as "die-swell" in which polymers swell in undesirable directions when passing through the exit port of an extruder (a machine for producing more or less continuous lengths of plastic sections).

Researchers have been adding small amounts of nanotubes--tiny tubes of carbon about 1,000 times thinner than a human hair--to polypropylene in hopes of dramatically enhancing the material's strength and other properties. Once realized, this enhanced polymer could be processed at high speed through extruders for use in manufacturing.

NIST materials scientists were concerned that because nanotubes make the polypropylene rubbery, the material would be difficult to process or its enhanced properties would be lost. To their surprise, the opposite proved true. When sheared (forced) between two plates, the polymer normally separates the plates. However, when nanotubes are added, the plates are pulled together.

The scientists discovered that this "pulling-together" completely alleviated die-swell. Industry currently uses various time-consuming trial-and-error solutions to deal with the problem.

Eliminating die-swell should help manufacturers improve their time-to-market by simplifying their die design processes and enabling the controlled manufacture of smaller components.