Self-cleaning 'Smart' Fabrics Capable of Environmental Toxin Remediation

Scientists at the Naval Research Laboratory's Center for Bio/Molecular Science and Engineering (CBMSE) have developed a new cost-effective, self-decontaminating ultrathin materials coating that actively destroys pesticides and related chemical agents on contact.

The coating neutralizes toxins instantly leaving no hazardous residue, which makes it ideal for use in protective clothing for military personnel and civilians. The coating can also be applied to materials used in filters for water purification, and in wipes for chemical spill clean-ups.

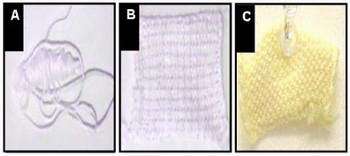

In the figure above, a cotton thread coated with the NRL film (A) was woven into a fabric (B). On contact with a pesticide solution, the fabric developed a yellow color (C) characteristic of degradation.

Unlike composite fabrics, where rubber or synthetic alternatives are sandwiched between layers, the NRL approach coats each individual thread before it's woven so that the fabric is treated throughout. This is significant in several ways. It will mean light, comfortable protective clothing that will draw off body moisture when used in warmer climates. And, because the coating is active throughout, it provides better protection against permeation and ensures the integrity of seamed areas on pieced fabric.

One challenge faced by the military is the problem of hazardous materials clean-up and/or disposal should a toxin exposure occur, says NRL principal investigator, Dr. Alok Singh. Coatings that simply collect molecules or toxins from the environment do so selectively and over time can actually produce a hazardous substance during the self-degradation process. The resultant substance can be a more potent toxin because it is then concentrated in the fabric. Because the NRL coating actually neutralizes the molecules on contact during the degradation process, it solves the problem of potentially dangerous and expensive remediation measures.

The NRL coating is actually an ultrathin, layered, composite film (500nm) containing enzymes that actively degrade chemical toxins. Compared to other degradation methods, the enzymes have shown longer active times and greater stability. The enzymes are also versatile as they can be selected for activity against specific target toxins. NRL researchers have successfully tested the coating on cotton fabric and glass cloth using pesticides, including the nerve agent simulant methyl parathion.

Further, the NRL coating is both cost-effective to produce and apply. The coating can be readily applied to substrates such as beads, fabrics, or paper by inexpensive methods such as dip coating, spin coating or spraying, adds Dr. Walter Dressick, a researcher working on the project. Fabrics made with the coating withstand repeated washing with water and are therefore reusable. Says Dr. Singh, "We have developed this coating to perform in a real-world environment."

Two patent applications are pending with the United States Patent Office (US Patent application numbers 10/750,637 Dec. 23, 2003 and 10/849,621 May 20, 2004). Technical details are described in "Self-cleaning fabrics for decontamination of organophosphorous pesticides and related chemical agents," Advanced Materials, vol. 16, pp 2112 (2004), authored by Alok Singh, Yongwoo Lee, and Walter J. Dressick.

The NRL technology is currently available for licensing to interested companies through the Laboratory's Technology Transfer program.

Source: Naval Research Laboratory