Biofuels from woody plants and grasses instead of the corn and sugarcane

Scientists are using biotechnology to chip away at barriers to producing biofuels from woody plants and grasses instead of the corn and sugarcane used to make ethanol.

NC State's Forest Biotechnology Group, which has been responsible for several research milestones published this year, summed up biofuel research progress and challenges for a special issue of the Plant Biotechnology Journal.

The greatest barrier to producing more sustainable and economical biofuels, according to lead author Dr. Quanzi Li, comes from stubborn plant cell walls that resist being broken down into biofuel ingredients. Cell walls contain desirable cellulose and hemicellulose, which is "covered up" with lignin, the substance that contributes to the strength of wood but gets in the way of biofuel production.

To make biofuel from wood, manufacturers must remove lignin and convert the cellulose to ethanol. Production begins with an expensive pretreatment, followed by enzyme use to release the sugars that can be fermented to produce ethanol.

Li says biotechnology research focuses on simplifying the process on several fronts.

Scientists have found ways to modify the cell wall structure to reduce the amount of lignin and change its makeup. They've manipulated the steps in hemicellulose formation and disrupted links between lignin and celluloses. To speed up biofuel production, they've introduced cell wall-degrading enzymes into plants, such as a bacterial gene that won't affect plants until it's activated at high temperatures during biofuel production.

NC State's team has created genetically modified trees with reduced lignin content – no small feat.

"Normally when you reduce lignin, plant growth is negatively affected, which also reduces biomass production," Li says. "However, we now know that we can produce transgenic plants with strong cell walls and normal development but much less lignin."

Fast-growing trees with high energy content could grow on marginal land without disrupting crop production.

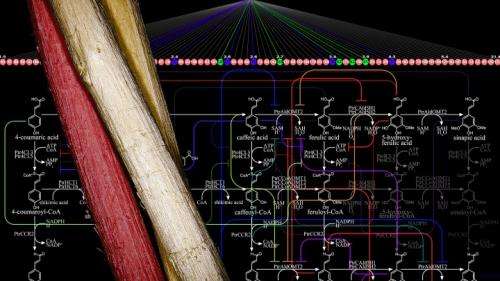

NC State has worked extensively with black cottonwood (Populus trichocarpa), a model tree species for biofuel production. Forest Biotechnology Group researchers in the College of Natural Resources have developed engineering models that predict how 21 pathway enzymes affect lignin content and composition, providing the equivalent of GPS directions to guide future research.

This comprehensive approach, which involves genes, proteins, plant chemical compounds and mathematical models, fits into a systems biology perspective that's the key to future breakthroughs, Li says.

"Progress has been made in many areas, but we still lack a complete understanding of how the cell wall is formed. We have to have a better idea of the factors that control its formation to produce better biomass for biofuels."

More information: Li, Q., Song, J., Peng, S., Wang, J.P., Qu, G.-Z., Sederoff, R.R. and Chiang, V.L. (2014) "Plant biotechnology for lignocellulosic biofuel production." Plant Biotechnol. J., DOI: 10.1111/pbi.12273

Journal information: Plant Biotechnology Journal

Provided by North Carolina State University