Researchers demonstrate new MEMS dynamic rheometer (w/ Video)

Researchers at the National Institute of Standards and Technology have demonstrated a microminiaturized device that can make complex viscosity measurements -- critical data for a wide variety of fields dealing with things that have to flow -- on sample sizes as small as a few nanoliters. Currently a table-top prototype, the NIST rheometer could be a particularly valuable tool for biotechnologists studying minute quantities of complex materials that must function in confined spaces.

Viscosity, elasticity and how materials flow when subject to a force is the subject of rheology, and the measurements tell a lot about a complicated material like a gel. Is it more like a liquid or a solid? By how much and under what conditions? The popular toy Silly Putty™ is a classic example of complex viscoelasticity, bouncing better than a rubber ball under a sharp, sudden force but slumping into a puddle when left alone.

One common way to make dynamic rheology measurements (how behavior changes with the speed or frequency of the applied force) is with a sizeable lab instrument that traps a test sample between a fixed plate and one that moves, and measures how much the thin layer of test material resists being deformed. Typical sample sizes are around a couple of milliliters, which doesn't sound like much, but, says polymer scientist Gordon Christopher, for some researchers it's a whole bunch.

"A lot of people in the biosciences are making very complex designer fluids based on proteins where you might make only 10 milliliters at a time. Polypeptide hydrogels for drug delivery or tissue replacement, for example," Christopher explains. "Their flow behaviors are very complicated and you really need to understand them, but in a traditional rheometer your sample for a single test is a large percentage of what you just spent two months making."

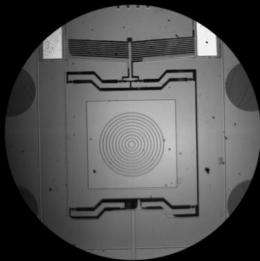

Inspired by a talk by a NIST scientist working on the design of novel nano positioning microelectromechanical systems (MEMS), team leader Kalman Migler and his colleagues began a collaboration to build a MEMS device that duplicated a classic sliding-plate dynamic rheometer—but in a space about one-twentieth the size of a postage stamp. The sample size of the MEMS rheometer is about 5 nanoliters. "With our device, if you gave me a milliliter of sample, I could give you back hundreds of tests," Christopher says.

Equally as important, he says, the MEMS rheometer inherently tests materials when they are confined in a very small space. For many biological applications where the material is meant to be used in a confined region like a blood vessel or the interior of a cell—or must be injected through a thin needle—understanding the flow characteristics of small amounts in a small space is more important than knowing how it behaves in bulk.

NIST's early prototype MEMS rheometers include only the core sliding plate mechanism on the MEMS chip, and rely on a microscope and high-speed cameras for the actual measurements. In a more polished version, according to the research team, the necessary sensors could be included on the chip and the entire instrument reduced to a handheld device for, e.g., quality control measurements on a plant floor.

The NIST MEMS dynamic rheometer is described in a new paper in Lab on a Chip.*

More information: * G.F. Christopher, J.M. Yoo, N. Dagalakis, S.D. Hudson and K.B. Migler. Development of aMEMS based dynamic rheometer. Lab Chip, 2010, Advance Article. DOI: 10.1039/C005065B

Provided by National Institute of Standards and Technology